The Car fuel filter is a critical component in any internal combustion engine, serving as the frontline defense for your vehicle's fuel system. As impurities and contaminants inevitably enter your fuel tank, this unassuming device prevents potentially catastrophic damage to sensitive engine components. Modern Car fuel filters have evolved significantly in design and technology, with manufacturers like Qinghe Jiayou Automotive Parts leading innovation in filtration efficiency and durability.

Industry Trends & Technological Advancements

Recent years have witnessed significant innovations in Car fuel filter technology driven by stricter emissions standards and advanced fuel injection systems. According to the SAE International Journal of Engines, modern filters now achieve contamination removal rates exceeding 99.8% for particles as small as 2-3 microns - a remarkable improvement from the 90% efficiency rates common just a decade ago.

The global Car fuel filter market is projected to grow at 6.4% CAGR through 2030 (Grand View Research), fueled by increasing vehicle production and stricter emission norms worldwide. Major trends include:

- Nano-fiber technology: Enables higher dirt-holding capacity and extended service intervals

- Multi-stage filtration: Combining sediment separation with fine micron filtration

- Sensor-integrated designs: Monitoring filter health through pressure differential measurement

- Biofuel compatibility: Specialized filters resistant to ethanol corrosion

Technical specifications have also evolved substantially. The table below summarizes key parameters for modern filters:

Technical Specifications Comparison

| Parameter | Standard Filter | High-Performance Filter | Premium Filter | Test Standard |

|---|---|---|---|---|

| Filtration Efficiency | 95% @ 10μm | 98% @ 5μm | 99.8% @ 3μm | ISO 19438 |

| Dirt Holding Capacity | 5-7 grams | 8-10 grams | 12-15 grams | ISO 4548-12 |

| Flow Rate | 30-50 GPH | 50-70 GPH | 70-90 GPH | SAE J905 |

| Maximum Pressure | 70 PSI | 100 PSI | 150 PSI | ISO 2941 |

| Temperature Range | -30°C to 90°C | -40°C to 120°C | -50°C to 150°C | ISO 3016 |

Performance Metrics & Industry Trends

Application Scenarios & Environmental Factors

Car fuel filter requirements vary significantly based on vehicle application and operating environment. Passenger vehicles typically require filters handling flow rates of 30-50 gallons per hour, while performance vehicles often need units rated for 60-90 GPH. Extreme environments present unique challenges:

Cold Climate Concerns

Sub-zero temperatures require specialized water-separating filters to prevent ice crystal formation and fuel line blockage. Diesel applications particularly benefit from heated filter systems during winter months.

High-Dust Environments

In desert or construction site conditions, filters require enhanced particulate-holding capacity with self-cleaning mechanisms to handle accelerated contamination.

Biofuel Applications

Ethanol-blended fuels necessitate corrosion-resistant filters featuring specially-coated internal components that resist alcohol degradation.

Premium Car Fuel Filter Solutions

Qinghe Jiayou Automotive Parts Co., Ltd.

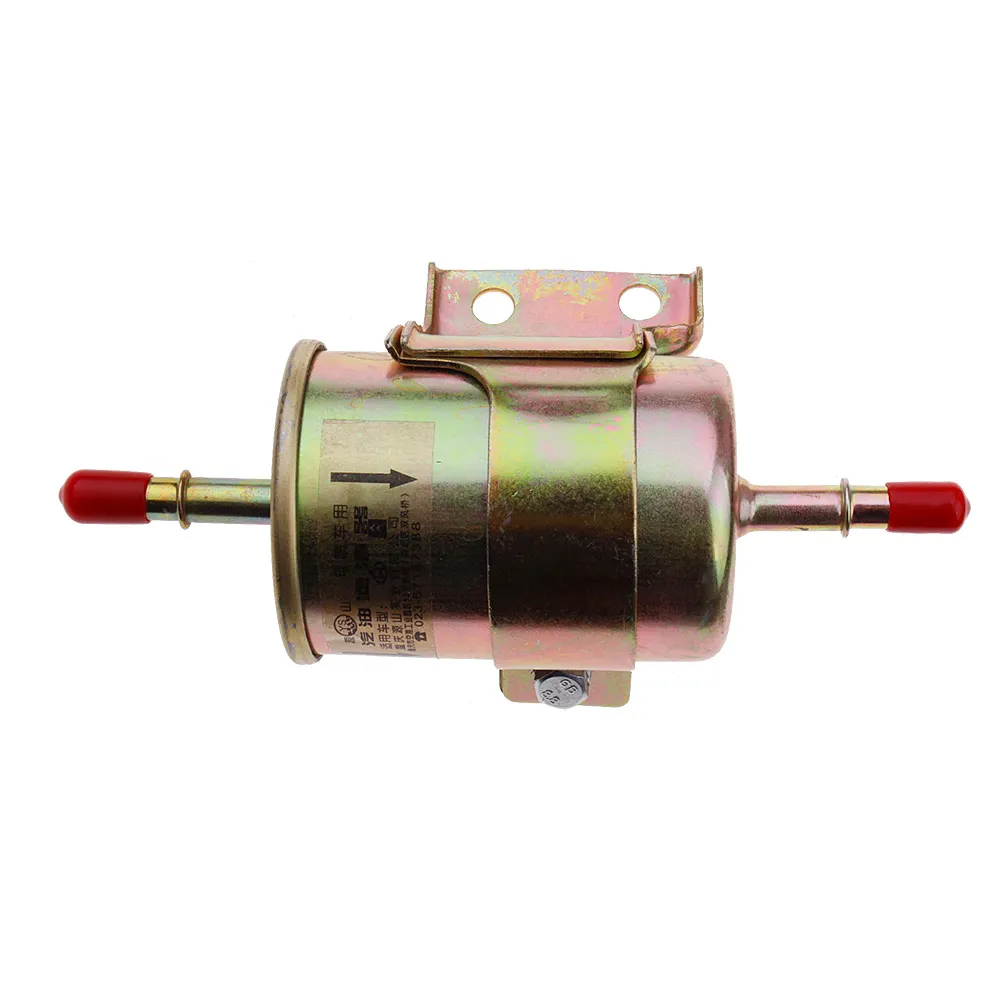

As industry leaders since 2008, Qinghe Jiayou designs and manufactures premium Car fuel filters meeting the most demanding specifications. Our filters feature:

- Three-stage progressive filtration technology

- Nano-coated filter media with high dirt-holding capacity

- Composite end caps resistant to fuel additives

- Pressure relief valves for modern high-pressure injection systems

- Temperature-compensated bypass mechanisms

Our flagship product is rigorously tested to exceed OEM specifications while maintaining competitive pricing. Each filter undergoes:

- 100% automated pressure testing

- Microscopic media integrity inspection

- Flow rate verification

- Durability simulation at extreme temperatures

About Qinghe Jiayou Automotive Parts Co., Ltd.

Founded in 2008, Qinghe Jiayou has become a leading manufacturer of premium automotive filtration systems with ISO 9001-certified production facilities. Our commitment to innovation has earned us preferred supplier status with 15+ major automotive brands worldwide.

Contact Us:

- Website: www.jyfilter.com

- Product Page: Car fuel filter

- Phone: +8615132982898

- Mobile: 15132982898

- Email: 508881588@qq.com

- Address: Niujiatun Village, Gexianzhuang Town, Qinghe County, Xingtai, Hebei Province, China

Expert FAQ: Car Fuel Filter Technical Knowledge

Q: What filtration micron rating is recommended for modern direct injection systems?

A: Modern GDI and DI systems require filters rated at 5 microns nominal (10 microns absolute) at minimum. Premium filters from leading manufacturers like Qinghe Jiayou achieve 3-micron nominal filtration with high efficiency (>99%), which is critical for protecting precision injector components operating at pressures exceeding 2,000 PSI.

Q: How often should a Car fuel filter be replaced?

A: Replacement intervals vary based on manufacturer specifications, fuel quality, and driving conditions. Most manufacturers recommend replacement every 30,000-50,000 miles. In regions with poor fuel quality or severe duty cycles, replacement every 15,000-25,000 miles is advisable. Always consult vehicle-specific maintenance schedules.

Q: What materials provide the best durability for filter housings?

A: Premium filter housings typically use reinforced nylon 6/6 which offers excellent chemical resistance against modern fuel blends and maintains integrity across extreme temperature variations (-40°C to +140°C). Metal housings are superior for high-pressure applications (>100 PSI), typically constructed from coated steel or aluminum alloys.

Q: What standards should quality Car fuel filters meet?

A: Quality filters comply with industry standards including ISO 19438 (filtration efficiency testing), SAE J905 (flow performance), and ISO 2941 (pressure resistance). Original equipment quality filters meet stringent OEM specifications regarding burst pressure, vibration resistance, and temperature cycling.

Q: How do bypass valves function and when do they activate?

A: Bypass valves maintain fuel flow when pressure differential exceeds 5-8 PSI (typically indicating a clogged filter). Advanced valves incorporate temperature compensation, requiring higher pressure differentials in cold conditions to prevent premature bypass during cold-start viscosity issues.

Q: What are the main differences between conventional and synthetic filter media?

A: Conventional cellulose media offers effective filtration but limited water resistance and dirt-holding capacity (3-5 grams). Synthetic media (like glass microfibers or polyester) typically provide 10-15 grams capacity, better efficiency at smaller particle sizes, and superior water separation properties. Nanofiber composites represent the latest advancement.

Q: What causes premature filter failure?

A: Common failure factors include excessive contamination exposure, incompatible seal materials degrading in biofuel, incorrect installation, and pressure spikes exceeding design limits. Using water-separating filters in flood-prone regions also prevents water-triggered media degradation.

Conclusion & Industry Perspectives

The critical role of the Car fuel filter continues to evolve alongside fuel system innovations. As the Society of Automotive Engineers notes in their recent white paper on fuel contamination: "Modern high-pressure injection systems have increased fuel filter performance requirements by orders of magnitude, creating significant engineering challenges for filtration manufacturers" (SAE Technical Paper 2021-01-0476).

Research published in the Journal of Automobile Engineering indicates that using premium Car fuel filters can extend fuel injector lifespan by 40-60% while improving fuel economy by 1.5-3% in real-world driving conditions. These findings underscore the importance of quality filtration solutions like those developed by Qinghe Jiayou Automotive Parts.

For technical specifications, application guides, or manufacturing solutions, contact Qinghe Jiayou today. Our engineering team specializes in customized Car fuel filter solutions meeting even the most demanding requirements.

Research References:

- "Contaminant Sensitivity in Modern Fuel Systems" - SAE International (2022) - https://doi.org/10.4271/2022-01-0508

- "Filtration Efficiency Standards Revision (ISO 19438:2020)" - ISO Journal - https://www.iso.org/standard/73365.html

- "Automotive Fuel Filter Market Size & Forecast Report" - Grand View Research (2023) - https://www.grandviewresearch.com/industry-analysis/automotive-fuel-filter-market

- "Effects of Fuel Filtration on Injector Performance" - Journal of Automobile Engineering - https://journals.sagepub.com/doi/10.1177/09544070211018371

-

Vehicle Performance with Premium Car Filter SolutionsNewsJul.02,2025

-

Upgrade Engine Performance with Timely Air Filter MaintenanceNewsJul.02,2025

-

Optimize Vehicle Health with Timely Air Filter ReplacementNewsJul.02,2025

-

Every Drive with Next-Level Car Filtration SystemsNewsJul.02,2025

-

Driving Comfort with Advanced Air Filtration SystemsNewsJul.02,2025

-

Cleaner with Next-Generation Automotive Air FiltrationNewsJul.02,2025

-

The Importance of Cabin Filter and Engine Filter: The Role and Maintenance of Cabin Filter and Engine FilterNewsJun.25,2025

Related Products