The car air filter is an often underestimated yet crucial automotive component that fundamentally safeguards engine performance, reduces emissions, and extends vehicle longevity. This guide offers a comprehensive breakdown covering latest industry trends, technical parameters, application contexts, manufacturing process, and car air filter price analytics, equipping professionals and vehicle owners with the insight needed to make informed decisions regarding replacement and customization.

1. Industry Overview: Car Air Filter Market 2024

According to Grand View Research, the global automotive air filters market size was valued at USD 6.1 billion in 2023 and is expected to reach USD 8.4 billion by 2028 (CAGR: 5.4%). The growth is attributed to rising vehicle production, stricter emission regulations (such as ISO 5011 standard), and end-user awareness regarding the impact of filtration efficiency on engine life.

- Top regions: North America, Europe, China, and Southeast Asia

- Key applications: Passenger cars, commercial vehicles, specialty vehicles (off-road, construction)

- Trends: Eco-friendly filter media, long-life synthetic filtration, integrated smart sensors

2. Car Air Filter Use and Working Principles

The car air filter is tasked with removing dust, micro-particulates, pollen, and debris from intake air before it enters the engine combustion chamber. Modern car air filters employ pleated, multi-layered media that traps particles as small as 1–5 microns.

- Maintains optimal air-fuel ratio for efficient combustion

- Reduces intake of abrasive contaminants, extending engine life

- Contributes to effective fuel economy and lowers NOx/CO2 emissions

- Prevents corrosion of engine internals (ISO 5011 tested dust capacity)

3. Technical Specifications & Product Parameter Table

Key technical indicators for modern car air filters:

| Parameter | Typical Value | Industry Standard | Impact |

|---|---|---|---|

| Filtration Efficiency (@1 micron) | 98%–99.7% | ISO 5011 | Engine protection |

| Dust Holding Capacity | 200g–600g | ISO 5011 | Service interval/life |

| Pressure Drop (ΔP) | ≤ 0.25 kPa | ANSI S12.15 | Engine power/efficiency |

| Airflow Capacity | 170–700 m³/h | OEM/SAE J726 | Vehicle size/application |

| Service Life | 15,000–45,000 km | OEM Spec | Replacement cycle |

| Material | Cellulose, Synthetic fiber, Activated Carbon | REACH, RoHS | Filtration & durability |

| Temperature Resistance | -40°C to 120°C | ISO 16750 | Under-hood reliability |

4. Car Air Filter Manufacturing Process (with Flowchart)

The advanced manufacturing of a car air filter involves precision engineering, strict quality control, and adoption of globally recognized standards (ISO 9001, ISO 5011). Here's a stepwise breakdown:

(Cellulose, Synthetic, Carbon) Filter Media Cutting

(CNC cutting, Tolerance ±0.15mm) Pleating Process

(Accordion pleats via automated line) End Cap Molding

(Injection molding, Polyurethane/ABS) Frame Assembly

(Ultrasonic welding for sealing) Quality Testing

(ISO 5011/ANSI bench, CAD inspection) Packaging & Shipping

(ESD, barcode, traceability)

Innovative technologies such as automated pleat formation, CAD-controlled die casting, and integrating RFID labels for traceability ensure every car air filter batch meets or exceeds industry benchmarks.

Process Diagram Video:

5. Car Air Filter Price & Life: Market Data

Car air filter price varies by material, size, OEM vs. aftermarket brand, and advanced features (e.g., activated carbon, HEPA-rated).

| Type | Average Price (USD) | Service Life (km) | Main Application |

|---|---|---|---|

| Standard Paper Filter | $5 – $18 | 12,000 – 18,000 | Passenger cars |

| Synthetic Fiber (Long-life) | $22 – $40 | 20,000 – 48,000 | Luxury/SUV/High mileage |

| Activated Carbon | $18 – $35 | 15,000 – 35,000 | Urban/smog/high traffic |

| High-Performance (HEPA/Performance) | $35 – $95 | 18,000 – 55,000 | Commercial, Performance, Racing |

6. Product Material, Testing & Technical Advantages

- Material: High-quality cellulose, synthetic nonwovens, or hybrid composites for maximum particulate capture and low flow resistance.

- Construction: Precision pleated media, multi-layer architecture, PU/ABS frames for anti-corrosion, ultrasonically welded seams.

- Testing & Certification: All batches undergo multi-phase testing (ISO 5011, SAE J726, RoHS/REACH compliance), including dust capacity, initial efficiency and final pressure drop.

- Lifetime: Typical car air filter life spans 15,000–45,000km, with long-life filters exceeding 50,000km under standard testing.

Car Air Filter Key Performance Comparison

7. Manufacturer Comparison: Leading Car Air Filter Brands

| Manufacturer | Origin | Main Product Line | Standards/Certifications | Key Customers |

|---|---|---|---|---|

| Germany | OEM, Aftermarket | ISO 9001, ISO 14001 | VW Group, Ford, Audi | |

Mahle Mahle |

Germany | Long-life, Carbon, Performance | ISO 5011, QS9000 | BMW, Mercedes-Benz |

MANN+HUMMEL MANN+HUMMEL |

Germany | Automotive & Industrial Filters | IATF 16949, ISO 13485 | Toyota, GM, Daimler |

| Japan | OE & Aftermarket | ISO 9001, ISO 14001 | Toyota, Honda | |

Fleetguard (Cummins) Fleetguard (Cummins) |

USA | Heavy-duty Vehicles | ISO 5011, ISO 14001 | Volvo, Cummins |

8. Customized Car Air Filter Solutions

Need a car air filter for challenging applications? JYFILTER supports full customization:

- Material selection for extreme dust, corrosive, or temperature environments

- Specialty coatings for anti-fungal or high-moisture applications

- OEM shape matching via 3D scanning and CAD reverse engineering

- Batch coding and RFID for traceability in fleet management

- Bulk procurement service with scheduled delivery and warehousing options

9. Application Scenarios & Project Cases

High-dust off-road trucks require car air filters with exceptional holding capacity (ISO 5011 Dust Class A Pass). The JYFILTER long-life filter demonstrated a 45% reduction in per vehicle downtime and lowered engine wear rates, confirmed by post-trial oil analysis.

OEM filter supply was replaced by a custom, anti-corrosion car air filter. Field-tested over 36,000 km, engine intake cleanliness improved, meeting ANSI/SAE J726 standard.

Activating predictive filter replacement, JYFILTER's RFID-coded filters enabled 20% longer operation cycles and improved EPA compliance based on real-world sensor data.

10. Service Commitment & Guarantees

- All car air filter series are certified per ISO/TS 16949, RoHS, REACH, and meet OEM warranty terms

- Standard lead time: 15–30 days upon confirmed order/specification

- Warranty: 24 months or 44,000km, whichever comes first

- Full technical support: CAD drawing review, installation guidance, and after-sales response within 24h

- Returns policy for product defects or shipment errors in 7 business days

11. FAQ: Professional FAQ on Car Air Filters

12. Car Air Filter — Related Charts & Data Visualization

2024 Market Share by Air Filter Type (Source: Grand View Research, Data Bridge Market Research)

13. References & Further Reading

- Grand View Research: Automotive Air Filter Market Size & Share Report, 2024

- SAE J726: Air Cleaner Test Code

- ISO 5011: Inlet Air Cleaning Equipment for Internal Combustion Engines – Performance Testing

- FilterForums: Car Air Filter Life Cycle & Replacement Intervals

- ResearchGate: Air Filter Materials for Automotive Applications

-

The Hidden Benefits of Proper Cabin Filter Use in Your VehicleNewsJul.31,2025

-

Replacing Your Gasoline Filter at HomeNewsJul.31,2025

-

How Often Should You Replace Your Car Air Cabin Filter?NewsJul.31,2025

-

How Much Does a Car Air Filter Cost?NewsJul.31,2025

-

Car Fuel Filter Price GuideNewsJul.31,2025

-

Best Car Air Purifiers for Allergy SufferersNewsJul.31,2025

-

Vehicle Performance with Premium Car Filter SolutionsNewsJul.02,2025

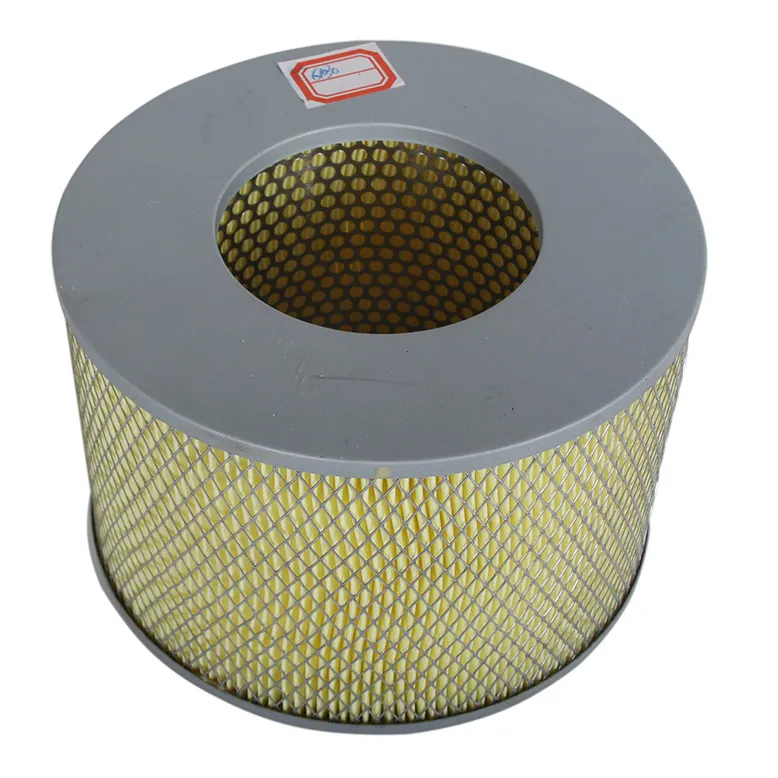

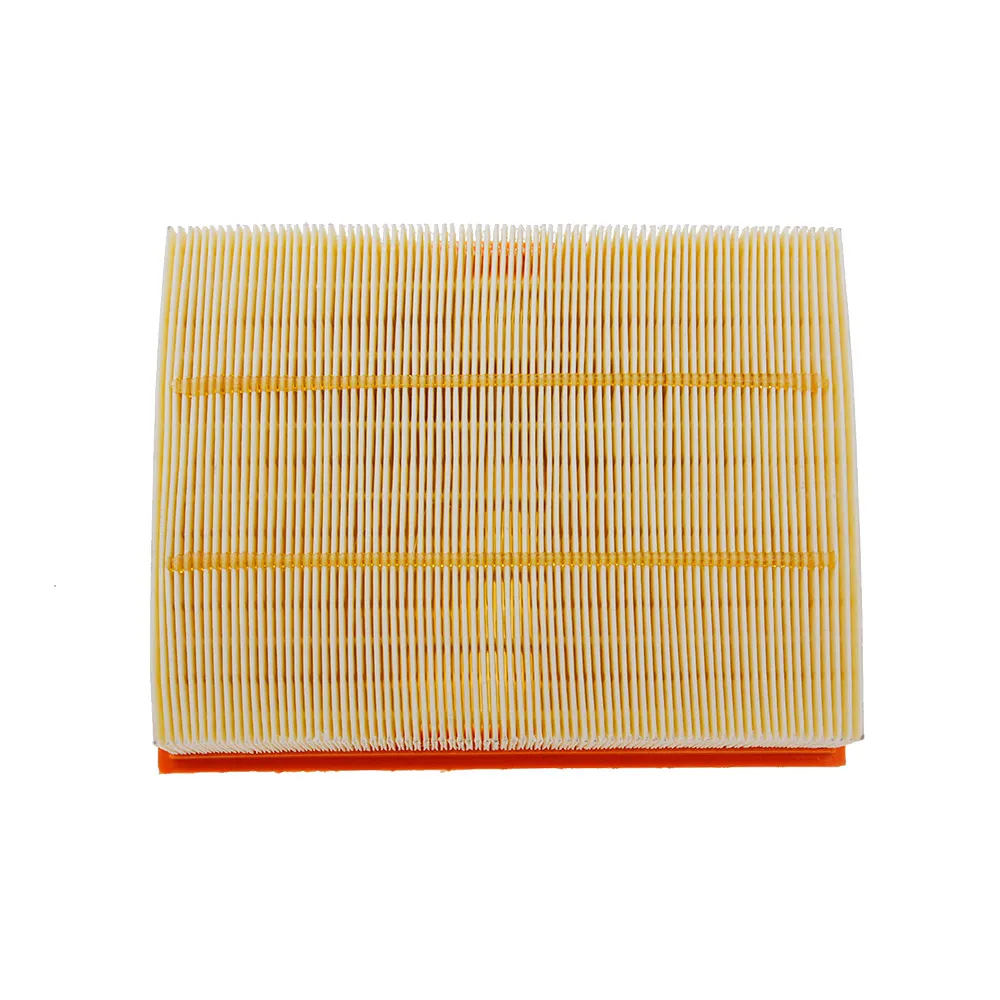

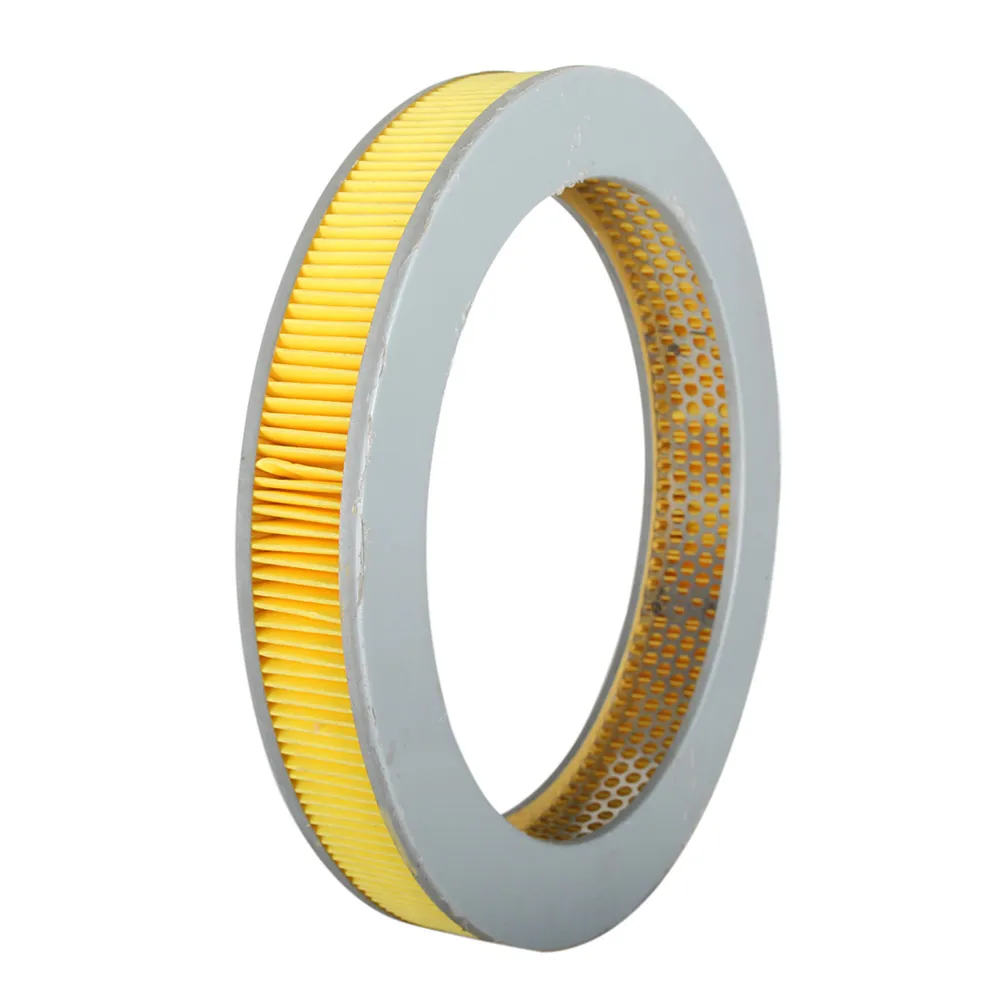

Related Products