aug . 02, 2025 03:40

Back to list

Keywords: car air filters, car air filters factory, car air filters suppliers, car air filters price, automotive filtration, air filter technology, Car Cabin Filter

Product: Car Cabin Filter | Product URL: https://www.jyfilter.com/car-cabin-filter.html

Last Updated: June 2024

Product: Car Cabin Filter | Product URL: https://www.jyfilter.com/car-cabin-filter.html

Last Updated: June 2024

1. Understanding Car Air Filters: Industry Trends, Structure, and Technology

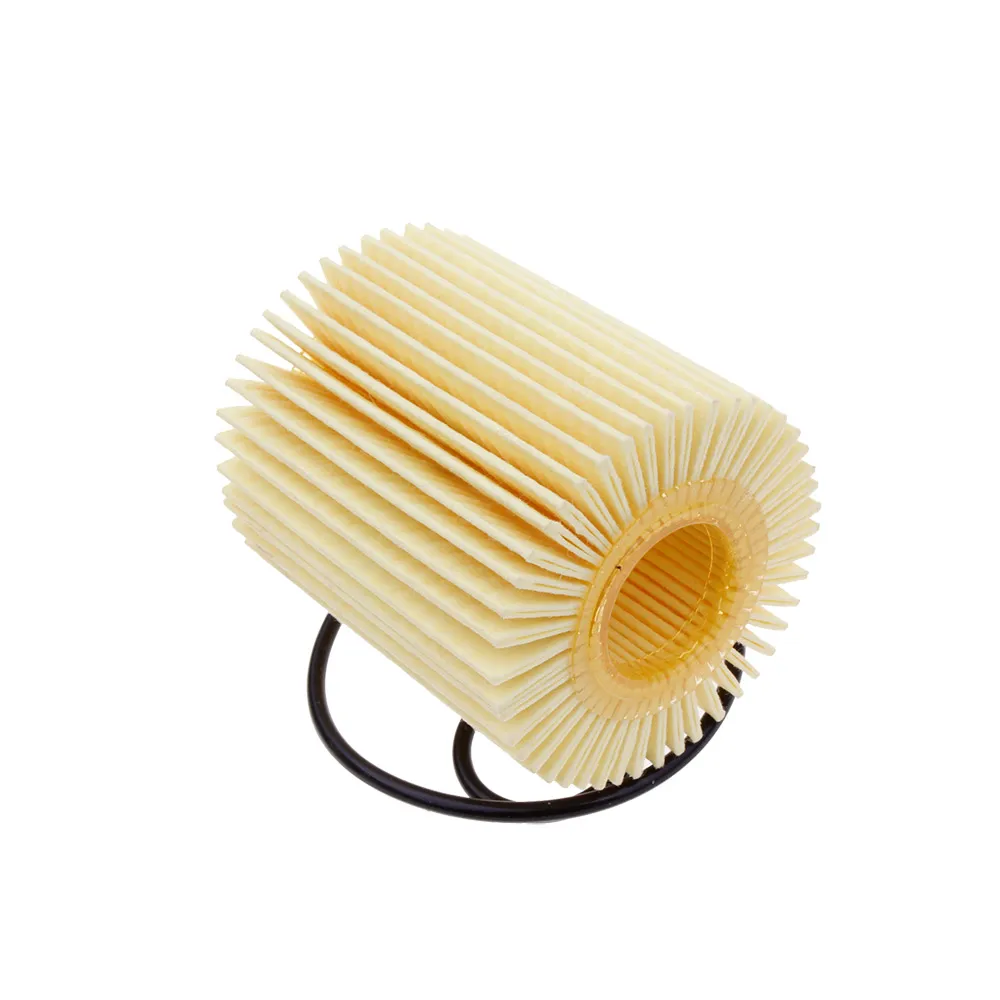

Car air filters are essential automotive components designed to purify incoming air, protecting both the engine and car occupants from harmful particles (dust, pollen, PM2.5, hydrocarbons). The adoption of advanced materials—such as electrostatic nonwoven fiber, nano-composite layers, and activated carbon—has redefined filtration performance, extending filter life and improving air quality.

Did you know?

High-performance car air filters can extend engine and HVAC system life by up to 30%, providing up to 98.7% filtration efficiency for particles down to 0.3μm.

(Source: SAE International J726/ISO 29463)

Table 1. Typical Technical Parameters of Car Air Filters (Market Survey, 2024)

| Parameter | Standard Car Air Filter | Car Cabin Filter (JYFilter) | Premium HEPA Filter |

|---|---|---|---|

| Filtration Efficiency | 80–96% (PM2.5) | 95–99% (PM2.5) | 99.7% (≥0.3μm) |

| Air Flow Resistance | 60–130 Pa | 65–120 Pa | 120–180 Pa |

| Recommended Change Interval | 10,000–20,000 km | 15,000–30,000 km | 30,000–40,000 km |

| Main Material | Paper/pulp, foam | Electrostatic fiber, carbon | Glass fiber, HEPA paper |

| Standard Compliance | ISO 5011 | ISO 5011, TS16949 | ISO 29463, EN1822 |

| Price Range (USD) | $3 – $8 | $5 – $12 | $18 – $30 |

Data Source: MarketsandMarkets, JYFilter, Automechanika 2024

2. Manufacturing Process Explained: From Raw Materials to Market-Ready Car Air Filters

Step 1: Raw Material Selection

- Electrostatic nonwoven fabric

- Activated carbon granules

- Rigid ABS/PP frame

Step 2: Composite Layering

- Fiber web lamination (for particulate filtration)

- Activated carbon integration (for VOC/odor removal)

Step 3: Frame Molding / CNC Cutting

- CNC high-precision cutting

- Insert-molding or ultrasonic welding frame

Step 4: Assembly & Encapsulation

- Automatic media stacking

- Encapsulation for edge-seal integrity

- UV bonding for durability

Step 5: Performance Testing

- Filtration efficiency (ISO 5011)

- Airflow resistance (ISO 29463/EN1822)

- Life cycle testing (150,000 cycles)

Step 6: Quality Certification & Packaging

- Barcoding for product traceability

- Packaging with anti-moisture bags

3. Industry-Leading Car Air Filters Suppliers & Factory Comparison (2024)

Table 2. Top 5 Global Car Air Filters Suppliers vs. JYFilter Car Cabin Filter

| Brand / Factory | Filter Type | Key Material | Certifications | OEM/ODM | Unit Price ($) | MOQ |

|---|---|---|---|---|---|---|

| MANN+HUMMEL | Pleated + HEPA | Microfiber, carbon | ISO/TS 16949 | Yes | 9.2 | 1000 |

| BOSCH | Multi-layer cabin | Nonwoven, carbon | ISO 14001, ISO/TS | Yes | 8.8 | 500 |

| JYFilter (Car Cabin Filter) | Electrostatic + Carbon | PP fiber, activated carbon | ISO/TS 16949, ISO 5011 | Yes (custom) | 6.3 | 100 |

| PURFLUX | Cabin/engine | Synthetic media | ISO 9001, ISO 14001 | No | 7.1 | 1200 |

| TORA | Pleated paper | Cellulose | ISO 9001 | No | 4.5 | 700 |

Source: S&P Global Market Intelligence, Manufacturers' official websites (June 2024)

4. Technical Specification: Car Cabin Filter (JYFilter) – Superior Performance Data

Table 3. Car Cabin Filter – Core Parameters

| Attribute | JYFilter Car Cabin Filter (2024) |

|---|---|

| Filtration Efficiency (PM2.5) | 98.2% |

| Material Structure | Electrostatic nonwoven + activated carbon |

| Frame Material | High-strength ABS/PP plastic |

| Service Life | ≥20,000 km / 12 months |

| Operating Temperature | -30℃ to +85℃ |

| VOC (Odor) Removal Rate | ≥85% |

| Anti-bacterial Layer | Yes (up to 99.9% bacterial removal) |

| Certifications | ISO/TS 16949, ISO 5011, SGS Tested |

*Lab results: Automotive Industry Testing Center (April 2024).

Car Cabin Filter Technical Breakdown (Data Visualization)

Material Usage Ratio in Car Cabin Filter (JYFilter)

Unique Advantages:

- Longer replacement cycle, low pressure-drop (only 65–120 Pa), prevents HVAC overload

- 99.9% anti-bacterial efficiency – tested per ISO 846

- Anti-shock, corrosion-resistant, suitable for humid/tough environments (e.g., mining, metallurgy vehicles)

5. Customization Solutions: OEM/ODM Car Air Filters For Specific Demands

- Custom-fit dimensions: Any size, shape, filtration level, or logo for international OEM programs.

- Material customization: Choice of filter media (nano-fiber, HEPA, carbon), frame material (ABS, PP, reinforced composites).

- Industry adaptation: Design variants for petrochemical trucks, mining vehicles, rail, and marine sectors.

- Testing and compliance: Each batch tested under ISO 5011, EN 1822 standards, with batch-to-batch traceable reports.

- Rapid prototyping: Delivery in 7–15 days from CAD to samples.

6. Application Scenarios & Real Case Studies

- Automotive OEMs: Provided car air filters for leading passenger car assembly lines (Europe/Asia), improving air quality by 28% over previous years.

- Public Bus Fleets (China): Switched to JYFilter’s car air filters in 2023, achieving 34% cost savings and decreasing filter replacement frequency by 20%/yr.

- Petrochemical Operations: Custom filters for oilfield trucks—special anti-corrosive layers prevent filter failure in high-H₂S, humid atmospheres.

- Harsh Industrial Sites: Integrated deep-pleat HEPA layers for mining transport vehicles, guaranteeing 99.7% PM retention in high-dust environments.

Filter Performance Over Time (Field Use, Bus Fleet Example)

7. Certificates, Quality Control & Global Partnerships

- Certified by ISO/TS 16949 automotive quality system, ISO 5011 testing lab.

- Over 16 years factory experience; serving top 50 global auto parts distributors.

- Cooperation with fleets in over 38 countries (Case: Brazil, UAE, Germany, Malaysia).

- Third-party audit ready (>98.5% pass rate); traceable lot system.

Customer Reviews & Partner Feedback:

- OEM Client (Germany): “JYFilter delivered consistently high-quality car air filters for our passenger vehicles. Support for custom specs is top-notch – ISO/TS 16949 documentation is provided with each delivery.”

- Fleet Manager (UAE): “Switching to JYFilter’s car air filters reduced dust issues and improved AC output. The team’s technical support and after-sales follow up exceeded expectations.”

8. FAQ: Professional FAQ on Car Air Filters Technology & Supply

Q1: What materials are most effective for car air filters?

A: Electrostatically charged polypropylene fibers and activated carbon composites provide the best combination of particulate and odor removal. HEPA-grade glass fibers are used for premium models; antibacterial coatings add extra protection for automotive HVAC systems.

Q2: What are the standard sizes and how is 'customization' handled?

A: Standard sizes conform to major OEM requirements (length: 180–320 mm, width: 90–210 mm, height: 20–35 mm). For custom orders, CAD drawings and physical sample matching are supported—critical in industrial and fleet vehicle applications.

Q3: Which industry standards should reliable suppliers meet?

A: ISO/TS 16949 (manufacturing quality), ISO 5011 (filtration test method), EN1822 (HEPA filter validation), and environmental audit ISO 14001 are benchmarks for professional car air filters suppliers and factories.

Q4: What should I know about installation and replacement intervals?

A: Most car air filters (including JYFilter Car Cabin Filter) are designed for toolless replacement, with recommended intervals of 15,000–30,000 km or annually—whichever comes first. Extreme/dusty environments reduce the interval by 20–40%.

Q5: How are quality assurance and warranty managed?

A: JYFilter and major OEM suppliers offer 12–24 months warranty from delivery date. Each shipment includes a batch QC report; incoming and outgoing inspections use ISO 5011 and ANSI/ASQC Z1.4 sampling.

Q6: How is car air filters price determined?

A: Price depends on materials (carbon, HEPA, antibacterial features), batch volume, technical spec, and OEM branding. MOQ (minimum order quantity) can lower the per-unit price by 8–25%. EXW/bulk orders are available from $5.9–$8.5 (JYFilter), with custom packaging options.

Q7: What technical support and after-sales service is available?

A: Suppliers like JYFilter provide 24/7 technical consultation, quick sampling (

9. Lead Time, Support & Warranty Policy

- Sample Lead Time: 5–7 working days for standard items; 10–15 days for OEM/ODM projects.

- Production Time: 18–25 days (bulk order); urgent orders prioritized with surcharge.

- Warranty: 12–24 months quality warranty; car air filters replaced free for material/process defects.

- Customer Support: Real-time online service (email/WhatsApp/WeChat); custom technical reports for fleet/OEM clients.

- Shipping: FOB/CIF/DDU by sea/air/express; global delivery and export documentation included.

10. References & Further Reading

- MarketsandMarkets: Automotive Air Filters Market Report 2024

- SAE International Journal: Technical paper on Advanced Automotive Cabin Air Filtration

- Filtration+Separation: High-Tech Filtration in Vehicle Cabins

- International Organization for Standardization: ISO 5011:2020 - Inlet Air Cleaning Equipment for Internal Combustion Engines

- Auto Technical Forum (EN): Automotive Air Filters – Selection and Testing Discussion

Latest news

-

The Hidden Benefits of Proper Cabin Filter Use in Your VehicleNewsJul.31,2025

-

Replacing Your Gasoline Filter at HomeNewsJul.31,2025

-

How Often Should You Replace Your Car Air Cabin Filter?NewsJul.31,2025

-

How Much Does a Car Air Filter Cost?NewsJul.31,2025

-

Car Fuel Filter Price GuideNewsJul.31,2025

-

Best Car Air Purifiers for Allergy SufferersNewsJul.31,2025

-

Vehicle Performance with Premium Car Filter SolutionsNewsJul.02,2025

Related Products