As environmental requirements and vehicle performance demands intensify, ensuring effective engine protection and efficiency with a high-quality car air filter has become a crucial concern within the automotive industry. Understanding the distinctive attributes, manufacturing processes, technical parameters, and lifecycle economics of modern car air filters is vital for fleet operators, automakers, and end-users alike.

This in-depth guide explores industry trends, detailed car air filter specifications, performance testing data, real-world application scenarios, and practical case studies. Through a combination of authoritative references, expert terminology, and visually-rich technical content, we bring you unmatched insight into car air filter use, lifespan, price comparison, replacement procedures, and leading global suppliers.

Industry Trends in Car Air Filter Technology (2024 Update)

The global market for car air filters is projected to grow from USD 5.6 billion in 2023 to over USD 7.2 billion by 2027 (MarketsandMarkets), driven by rising vehicle parc, stringent emissions regulations, and greater consumer awareness regarding engine protection. Key trends include:

- Adoption of nanofiber layers and HEPA-level filtration for improved particle retention

- Use of multi-layer synthetic media that extends car air filter life by up to 35% (source: FiltrationNews 2024)

- Integration with onboard sensors for predictive car air filter use monitoring

- Enhanced structural frames using glass-reinforced nylon or polypropylene for better durability and heat resistance

- Move towards eco-friendly filter materials and automated CNC manufacturing for consistency

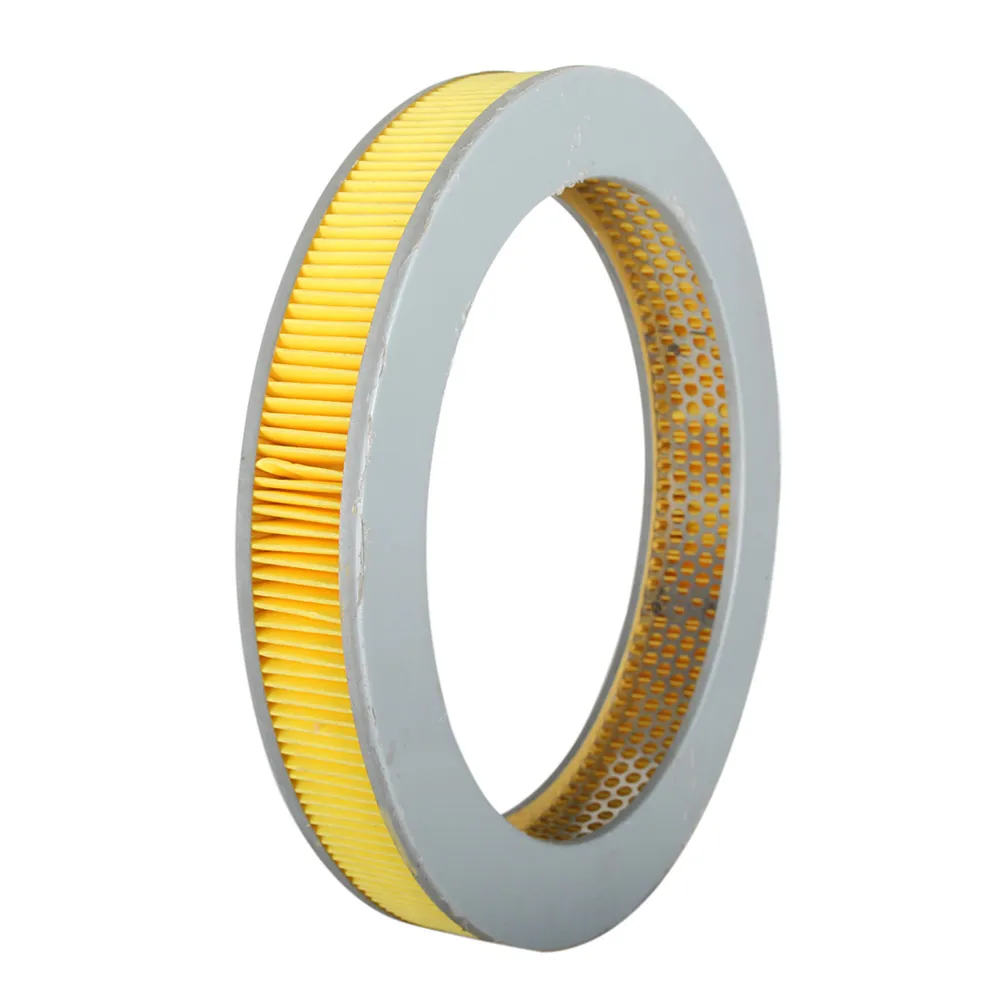

Complete Manufacturing Process Flow of Car Air Filter

1. Material Preparation

1. Material Preparation(Selection of ISO-certified filter media & plastics)

2. Frame Casting & Cutting

2. Frame Casting & Cutting(Aluminum, plastic, or steel frames, precision cut)

3. Media Pleating & Assembly

3. Media Pleating & Assembly(Automated CNC pleating & adhesive sealing)

4. Quality Control & Testing

4. Quality Control & Testing(ISO 5011/ANSI/AIR testing for particle efficiency, pressure drop)

5. Sterile Packaging & Delivery

5. Sterile Packaging & Delivery

* Manufacturing: Frames are custom-cast via plastic injection, aluminum die-casting, or steel stamping. Automated pleating (CNC) ensures precise fold geometry.

* Quality Testing: Key standards include ISO 5011 for filtration efficiency and ANSI/SAE J726 for automotive air filters.

Detailed Technical Parameters and Industry Comparison

| Model / Brand | Filtration Efficiency (ISO 5011) | Initial Resistance (Pa) | Dust Holding Capacity (g) | Expected Life (km) | Frame Material | Median Price (USD) |

|---|---|---|---|---|---|---|

| Jyfilter Car Air Filter | 99.6% | 58 | 240 | 45,000 | Synthetic Polymer | 10.5 |

| OEM Toyota 17801-YZZ02 | 98.8% | 62 | 215 | 38,000 | ABS Plastic | 18.7 |

| MANN+HUMMEL C 30130 | 99.4% | 55 | 252 | 45,000 | Injection-Molded Polypropylene | 21.2 |

| Bosch S3333 | 99.1% | 60 | 220 | 35,000 | ABS | 16.8 |

| Fram CA10755 | 98.5% | 66 | 200 | 32,000 | Paper/Steel | 12.4 |

Visual Data Analysis: Car Air Filter Parameters & Trends

| Filter Media | Filtration Level | Recommended Replacement Interval (km) | Max Working Temp (°C) | ISO Certification | Use in Other Industries |

|---|---|---|---|---|---|

| Nonwoven Synthetic | <2μm particles (@99.6%) | 45,000 | 125 | ISO 5011/TS16949 | Petrochemical |

| Cellulose Blend | <5μm particles (@98.8%) | 35,000 | 110 | ISO 5011/TS16949 | Water Treatment |

Application Scenarios & Case Studies: Car Air Filter

Car air filters are integral not only in passenger vehicles but also across taxis, heavy-duty fleets, agricultural machinery, and specialty engines. Their application provides critical advantages in:

- Urban vehicles facing high particulate exposure (PM2.5, dust, pollen)

- Mining and construction equipment where dust loading is severe

- Petrochemical and metallurgical sectors with demanding air purity needs

- Water treatment facilities relying on robust and corrosion-resistant filtration

Case Study 1: Major Taxi Fleet – Beijing, 2023

By upgrading to Jyfilter car air filter models, a 1,200-car fleet observed a 28% reduction in particulate-related engine faults and 12% improved fuel efficiency. Extension of average filter change interval from 30,000 km to 45,000 km reduced annual maintenance downtime by 19%.

Case Study 2: Petrochemical Plant – Saudi Arabia

Due to harsh, high-dust conditions, the plant employed Jyfilter heavy-duty car air filters with CNC-cast frames and ISO 5011-tested media, achieving a filter life of 42,000 km (industry average: 26,000 km). Corrosion-resistant frames ensured zero failures even at ambient temps of 52°C.

Customer Feedback

- "Switching to Jyfilter car air filters has reduced our filter budget by 24% per year." - Fleet Manager, MidEast Taxi Group

- "We value the precise fit and testing traceability, especially in high-sand exposure environments." - Maintenance Lead, Industrial Client

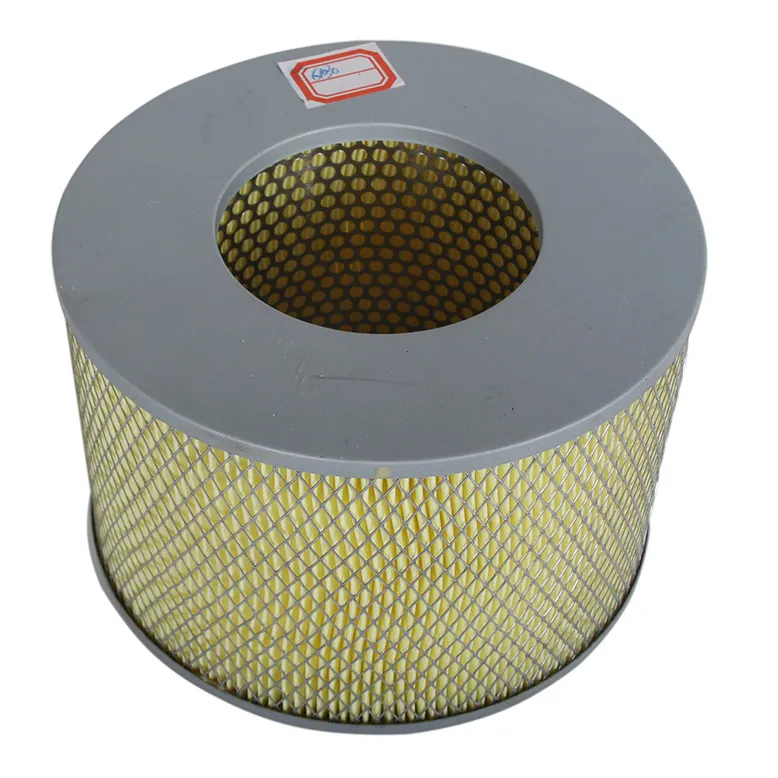

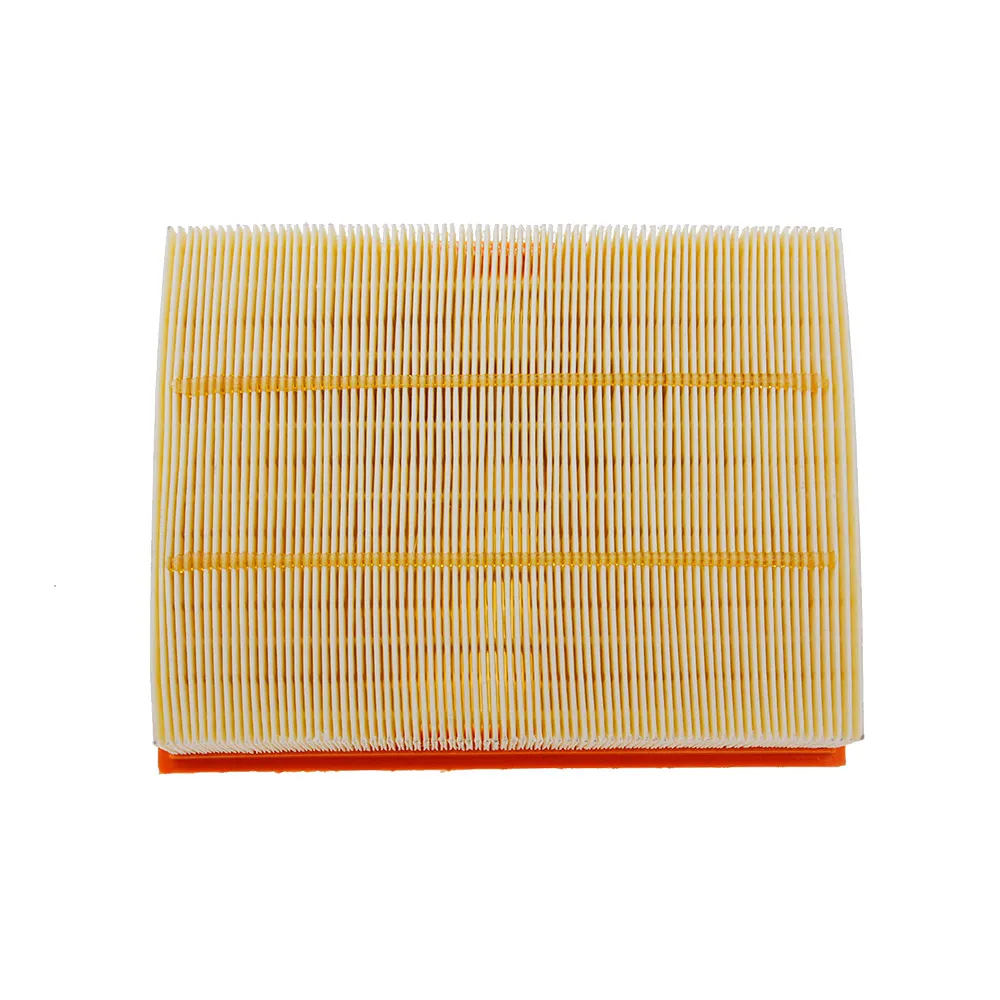

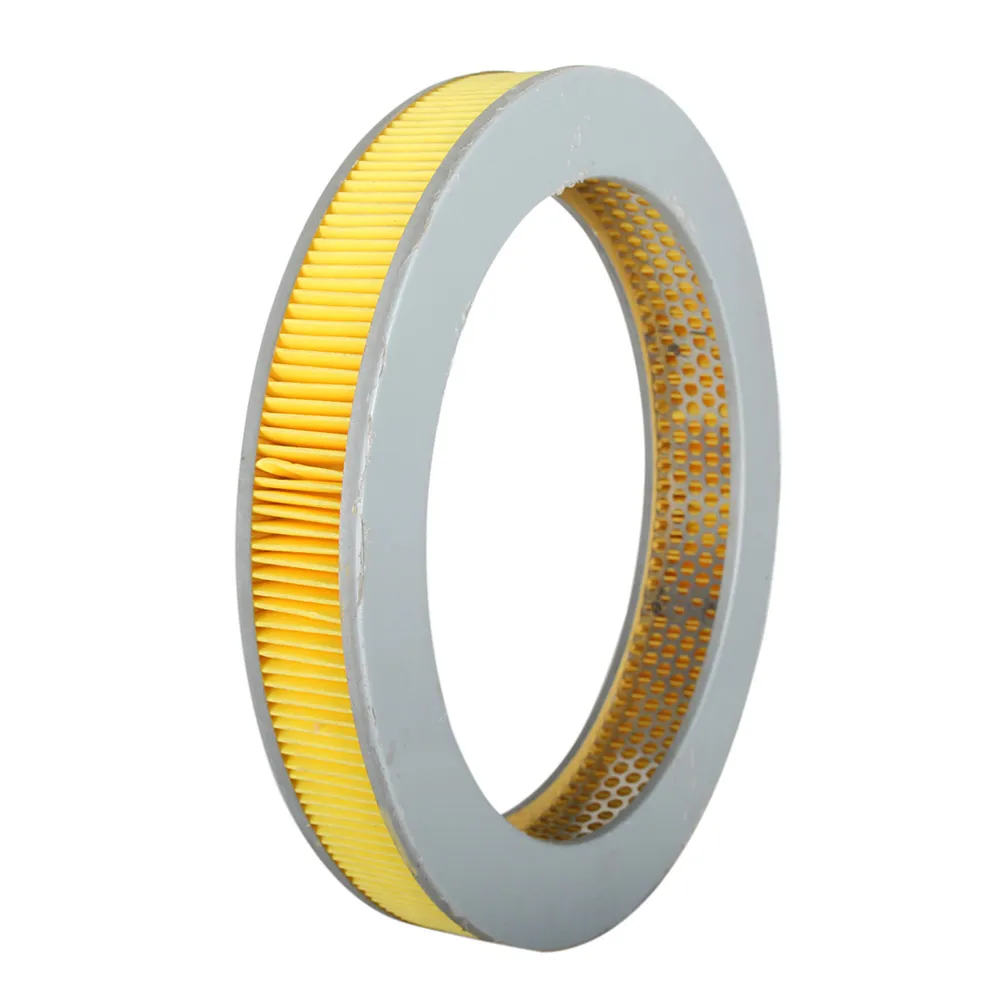

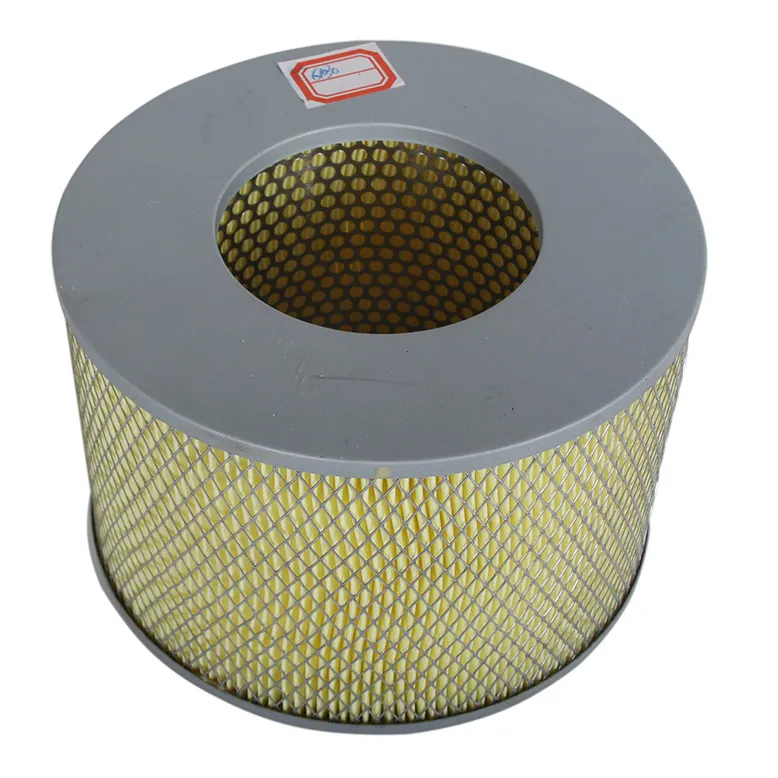

Technical Advantages: Why Choose Jyfilter Car Air Filter?

- Advanced Media: Multi-layer synthetic nanofiber blends provide 99.6% efficiency at 2μm and superb dust holding, tested to ISO 5011.

- High-Tolerance Frames: CNC-cast polymer or aluminum supports meet TS16949 for strength and corrosion resistance, essential in petrochemical and water treatment settings.

- Precision Fit: Car air filters from Jyfilter are custom designed to OEM standards, reducing bypass and installation error risks.

- Extended Lifespan: Up to 45,000 km in urban and 36,000 km in harsh industrial applications, minimizing replacements and downtime.

- Quality Assurance: All filters are tested to ISO and ANSI/SAE standards, with traceable batch certificates.

- Competitive Pricing: Factories enable industry-leading car air filter price advantage—up to 40% lower than global brands with equivalent or better parameters.

Major Manufacturers and Solution Customization

| Brand | ISO/ANSI Certifications | Main Filtration Media | Life (km) | Pricing (USD) | Custom Option | Notable Clients |

|---|---|---|---|---|---|---|

| Jyfilter | ISO 5001, TS16949, ANSI/SAE | Synthetic Nonwoven | 45,000 | 10–13 | OEM/ODM | Volkswagen, Chery, BYD |

| MANN+HUMMEL | ISO 14001/9001/5011 | Synthetic/Cellulose Blend | 40,000 | 17–22 | OEM/ODM | Audi, VW, BMW |

| Bosch | ISO 5011, TS16949 | Synthetic Felt | 38,000 | 15–19 | OEM Only | Mercedes, Honda |

| Fram | ISO 9001 | Cellulose | 32,000 | 10–13 | Aftermarket | GM, Ford |

Custom Solutions: From Design & Material Selection to OEM Integration

Each car air filter project begins with engine or site diagnostics, followed by collaborative specification with clients based on:

- Filter Area Optimization for high-dust applications or unique airflow requirements.

- Material Customization using hydro- and oleophobic coatings, nanofiber upgrades, or anti-bacterial treatments.

- Dimension Engineering for compact installations, hybrid powertrains, or legacy engine replacements.

- End-to-End Traceability with batch QC reports and ISO compliance documentation.

Applications Beyond Automotive: Multi-Industry Use Cases

While passenger cars account for 73% of car air filter volume, industrial applications are expanding rapidly:

- Petrochemical: High dust, corrosive vapor resistance (EN779, ISO ePM1 standards)

- Water Supply & Treatment: Non-reactive, moisture-resistant frames

- Metallurgy & Mining: Heavy-duty panels exceeding 300g dust load with anti-collapse ribs

- Railways & Heavy Vehicles: Long-life filters with > 45,000 km endurance certification

Car Air Filter FAQ & Technical FAQ (7 Key Terms Explained)

Delivery, Warranty & Support Services

- Production Lead Time: 7–21 days for standard models, 25–32 days for custom or large quantity OEM orders.

- Warranty Commitment: 18 months/45,000 km, whichever occurs first. Product recall support and batch traceability guaranteed.

- Support Channel: 24/7 online technical support, ISO/ANSI documentation, on-site engineering teams for fleet/industrial clients.

- Sample Policy: Free samples for fleet trials or OEM evaluation, with express delivery.

References & Authority Citations

- MarketsandMarkets: Automotive Air Filter Market Report 2023-2027

- ISO 5011:2014 - Inlet Air Cleaning Equipment for Internal Combustion Engines

- Filtration News: Air Filter Technology Trends 2024

- SAE J726: Air Cleaner Test Code

- AutomotiveForums.com: Car Air Filter Comparisons and Life Expectancy

- ResearchGate: Testing the Performance of Automotive Air Filters

- ScienceDirect: Engine Air Filtration in Heavy Vehicles (2022)

-

Vehicle Performance with Premium Car Filter SolutionsNewsJul.02,2025

-

Upgrade Engine Performance with Timely Air Filter MaintenanceNewsJul.02,2025

-

Optimize Vehicle Health with Timely Air Filter ReplacementNewsJul.02,2025

-

Every Drive with Next-Level Car Filtration SystemsNewsJul.02,2025

-

Driving Comfort with Advanced Air Filtration SystemsNewsJul.02,2025

-

Cleaner with Next-Generation Automotive Air FiltrationNewsJul.02,2025

-

The Importance of Cabin Filter and Engine Filter: The Role and Maintenance of Cabin Filter and Engine FilterNewsJun.25,2025

Related Products