In the complex symphony of an internal combustion engine or electric vehicle drivetrain, various components work in harmony to deliver power, efficiency, and longevity. Among these, automotive filters stand out as critical, albeit often overlooked, guardians. From protecting delicate engine parts from microscopic contaminants to ensuring optimal fluid purity, these essential components play a pivotal role in vehicle reliability and environmental compliance. This comprehensive guide delves into the world of **automotive filters**, with a specific focus on the vital car fuel filter, exploring their technology, application, and the industry standards that define their performance.

Industry Trends and Technological Advancements in **Automotive Filters**

The global **automotive filters** market is undergoing significant transformation, driven by stringent emission regulations, the increasing adoption of Gasoline Direct Injection (GDI) and high-pressure common rail diesel systems, and the burgeoning electric vehicle (EV) sector. Modern engines demand cleaner fuel and air to operate efficiently and meet Euro 6 or EPA Tier 3 emissions standards. This has spurred innovations in filter media, design, and manufacturing processes, leading to higher filtration efficiency, extended service intervals, and reduced environmental impact.

Key Trends Shaping the **Automotive Filters** Landscape:

- Enhanced Filtration Efficiency: The push for cleaner engines necessitates filters capable of capturing even finer particles, often down to sub-micron levels, particularly for fuel and oil filtration. This is crucial for protecting precision components in GDI systems, where fuel injectors operate at extremely high pressures and tight tolerances.

- Lightweighting and Compact Design: Manufacturers are continually striving to reduce the weight and size of automotive filters to contribute to overall vehicle weight reduction, improving fuel economy and reducing emissions. This involves innovative materials and integrated designs.

- Sustainable Materials: A growing emphasis on environmental sustainability is leading to the development and adoption of recyclable, biodegradable, and renewable filter media materials, reducing the ecological footprint of filter disposal.

- Smart Filters and Sensors: The integration of sensors into automotive filters allows for real-time monitoring of filter condition, alerting drivers or maintenance systems when a filter needs replacement. This optimizes maintenance schedules and prevents premature failures.

- Electrification's Impact: While EVs reduce the need for traditional engine air and fuel filters, they introduce new filtration challenges, such as cabin air quality, battery thermal management system filters, and cooling fluid filters. This represents a new growth area for **automotive filters** manufacturers.

Fig 1: Advanced filtration media designed for optimal performance in modern vehicles.

According to a report by Grand View Research, the global **automotive filters** market size was valued at USD 17.5 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 4.5% from 2023 to 2030, driven by the increasing vehicle parc and stringent emission norms. This underscores the sustained demand and crucial role of these components.

The Critical Role of the Car Fuel Filter: Technical Parameters and Application Scenarios

Among the various types of **automotive filters**, the car fuel filter holds paramount importance. Its primary function is to remove impurities, such as dirt, rust, scale, and other contaminants from the fuel, before it reaches the fuel pump and injectors. Even microscopic particles can cause significant damage to precision fuel system components, leading to reduced engine performance, increased emissions, and costly repairs. The car fuel filter is essential for both gasoline and diesel engines, adapting its design to the specific needs of each fuel type.

Technical Parameters of a High-Performance Car Fuel Filter:

- Micron Rating: This specifies the smallest particle size the filter can capture. For modern GDI engines, fuel filters often feature ratings as low as 5-10 microns to protect sensitive injectors. Diesel fuel filters may go even lower, sometimes down to 2-5 microns, due to the high precision of diesel injection systems.

- Flow Rate: The filter must allow sufficient fuel flow to meet the engine's demands at all operating speeds and loads, without causing a significant pressure drop. An inadequate flow rate can lead to fuel starvation and engine stuttering.

- Pressure Drop: This measures the resistance to fuel flow across the filter media. A lower pressure drop indicates better flow characteristics and less strain on the fuel pump. Excessive pressure drop can hinder fuel delivery and reduce pump lifespan.

- Filtration Efficiency: Expressed as a percentage, this indicates how much of a given contaminant size is removed. For example, a 98% efficiency at 10 microns means the filter removes 98% of all particles 10 microns or larger.

- Contaminant Holding Capacity (Dust Holding Capacity): This refers to the amount of dirt the filter can hold before it becomes clogged and significantly restricts flow. A higher capacity means a longer service life.

- Operating Temperature and Pressure: Filters must be designed to withstand the operating temperatures and pressures of the fuel system, which can vary widely depending on engine type and driving conditions.

- Material Compatibility: The filter media and housing materials must be compatible with various fuel additives, ethanol (for gasoline), and biodiesel (for diesel) to prevent degradation and ensure long-term integrity.

Fig 2: Dissected view of a car fuel filter showing internal components and media.

Application Scenarios of Car Fuel Filter:

The car fuel filter is a universal component across various vehicle types and fuel systems:

- Passenger Cars (Gasoline and Diesel): Crucial for protecting fuel injectors, fuel pumps, and carburetors from contaminants. Regular replacement ensures optimal engine performance and longevity.

- Commercial Vehicles (Trucks, Buses): Given their high mileage and demanding operating conditions, commercial vehicles rely heavily on robust fuel filtration to minimize downtime and maintenance costs. Diesel engines, in particular, benefit from multi-stage filtration systems that often include a water separator.

- Off-Road Vehicles and Heavy Equipment: Operating in dusty and harsh environments (e.g., construction, agriculture, mining), these vehicles face extreme contamination risks. High-capacity, durable fuel filters are essential.

- Marine Engines: Boats and marine vessels require specialized fuel filters to contend with moisture and potential fuel degradation in marine environments.

- Power Generators: Stationary engines used for power generation, often running on diesel, also depend on efficient fuel filtration for reliable operation and extended service life.

The concept of an inline car fuel filter is common, where the filter is placed directly in the fuel line between the fuel tank and the engine. Many modern vehicles integrate the fuel filter within the fuel tank itself, often as part of the fuel pump assembly, known as an in-tank fuel filter. The universal car fuel filter, designed to fit a broad range of older or custom applications, provides flexibility but requires careful matching to ensure proper flow and filtration for specific engine demands. The car fuel filter price varies significantly based on its design, material, brand, and vehicle application, ranging from a few dollars for simple inline filters to over a hundred for integrated, high-performance units for luxury or specialized vehicles.

Manufacturing Process of **Automotive Filters** (Focus on Car Fuel Filter)

The manufacturing of **automotive filters** is a sophisticated process that combines precision engineering, material science, and stringent quality control. Below is a detailed overview of the typical manufacturing process for a car fuel filter, emphasizing critical stages and technologies.

Detailed Manufacturing Workflow:

Visual Aid Concept: Imagine a flow chart with arrows, starting from raw materials and leading through each step, with small icons or descriptions for each stage.

[Please imagine or embed a schematic diagram/short video link here showing the process]

View our product video for a glimpse into our manufacturing excellence!

- Raw Material Preparation:

- Filter Media: High-quality filter paper (cellulose, synthetic fibers, or a blend), often impregnated with resins for strength and chemical resistance, is critical. For fuel filters, synthetic media like micro-fiberglass or polypropylene are increasingly used due to their superior efficiency and moisture resistance.

- Housing Materials: Steel (often galvanized or coated for corrosion resistance), aluminum, or high-performance plastics (like nylon 6/6 or polypropylene) are chosen based on strength, weight, and compatibility with fuel types. These are typically prepared via stamping, deep drawing (for metal), or injection molding (for plastic).

- End Caps and Gaskets: Steel or plastic end caps provide structural integrity, while rubber or silicone gaskets ensure a leak-proof seal.

- Media Pleating and Forming:

- The flat filter media is precisely pleated using specialized machinery. Pleating increases the effective surface area, enhancing contaminant holding capacity and filter lifespan without increasing the physical size of the filter. Pleat depth and count are critical parameters optimized for flow and filtration efficiency.

- For some designs, the pleated media is then formed into a cylindrical shape.

- Assembly of Filter Element:

- The pleated media cylinder is affixed to the end caps using strong adhesives (e.g., epoxy resins) or mechanical crimping. This creates a robust filter element.

- An inner core (perforated metal or plastic tube) is often inserted to provide structural support and prevent media collapse under pressure, especially important for high-pressure fuel systems.

- Housing Manufacturing:

- Casting/Forging (Less Common for Filters, More for Components): While main filter housings are typically stamped or molded, some specialized filter components, like complex manifold interfaces or heavy-duty industrial filter heads, might involve casting or forging for extreme strength and precision.

- CNC Machining (for Precision Components): For highly critical components requiring extremely tight tolerances, such as fuel filter adapters or specialized fittings, CNC machining is employed to achieve precise dimensions and surface finishes.

- Welding/Sealing: For metal housings, components are welded together (e.g., resistance welding, laser welding) to create a sealed unit. For plastic housings, ultrasonic welding or heat sealing is common.

- Element Insertion and Final Assembly:

- The assembled filter element is carefully inserted into the manufactured housing.

- Gaskets and seals are put into place to ensure a hermetic seal once the housing is closed.

- The housing is then sealed, often by crimping the metal housing, screwing together plastic components, or using specialized sealing processes.

- Testing and Quality Control:

- Leak Testing: Each filter undergoes pressure testing to detect any leaks and ensure integrity.

- Flow Rate and Pressure Drop Testing: Filters are tested to verify they meet specified flow rates and pressure drop characteristics, often according to standards like ISO 4548 for full-flow oil filters or SAE J905 for fuel filters.

- Burst Pressure Testing: Filters are subjected to extreme pressure to determine their burst strength, ensuring they can withstand transient pressure spikes in the fuel system.

- Filtration Efficiency Testing: Sample filters are rigorously tested for their ability to remove contaminants at various micron levels, often using multi-pass test methods (e.g., ISO 16889 for hydraulic filters, adapted for fuel filters) with calibrated test dust.

- Vibration and Durability Testing: Filters are subjected to simulated vehicle vibrations and temperature cycles to assess their long-term durability and structural integrity under real-world conditions.

- Compliance Checks: Ensuring adherence to industry standards like ISO 9001 (Quality Management), IATF 16949 (Automotive Quality Management), and specific OEM (Original Equipment Manufacturer) requirements.

- Packaging and Shipping:

- Finished filters are cleaned, labeled with part numbers and manufacturing dates, and packaged to prevent damage during transit and storage.

Fig 3: Precision assembly line for automotive filters ensuring consistent quality.

The lifespan of a car fuel filter can vary from 30,000 to 100,000 miles (or 2-5 years) depending on vehicle manufacturer recommendations, fuel quality, and driving conditions. Regular maintenance, including timely filter replacement, is key to maximizing its effective usage and preventing engine problems.

Technical Advantages and Manufacturer Comparison

Choosing the right **automotive filters**, especially a car fuel filter, means understanding the technical advantages offered by leading manufacturers. Our Car fuel filter (Product URL: https://www.jyfilter.com/car-fuel-filter.html) excels in several key areas:

Key Technical Advantages:

- Superior Filtration Media: Utilizing multi-layered synthetic media ensures exceptional particle removal efficiency, protecting sensitive fuel injectors in GDI and common rail systems. This translates to prolonged engine life and consistent fuel delivery.

- Robust Construction: Our filters feature corrosion-resistant housings (e.g., treated steel or high-grade polymers) and durable seals, engineered to withstand extreme temperatures, pressures, and harsh fuel chemistries (including biofuels).

- Optimized Flow Dynamics: Designed for minimal pressure drop, our car fuel filter ensures unimpeded fuel flow, preventing fuel pump strain and ensuring peak engine performance across all RPMs.

- High Contaminant Holding Capacity: Advanced media structure allows for a higher dirt-holding capacity, extending service intervals and reducing the frequency of replacements, which is a significant advantage for commercial fleets and everyday drivers seeking lower maintenance costs.

- Water Separation Capability (for Diesel Filters): Our diesel fuel filters incorporate advanced water separation technologies, critical for preventing water damage to diesel injection systems, which are highly susceptible to corrosion and cavitation from water in fuel. This directly contributes to anti-corrosion benefits.

- Compliance with International Standards: Our products meet or exceed international standards such as ISO 9001 for quality management and adhere to relevant SAE, DIN, and OEM specifications, ensuring reliability and compatibility.

- Energy Efficiency: By ensuring clean fuel delivery, our filters contribute to optimal fuel atomization and combustion, indirectly leading to improved fuel efficiency and reduced emissions (energy saving).

Typical **Automotive Filters** Parameters & Comparison

Below is a comparative table illustrating common parameters for various types of automotive filters and how our Car fuel filter product compares, emphasizing its technical superiority.

| Parameter | Typical Value (Generic Filter) | Our Car Fuel Filter (JYFilter) | Benefit |

|---|---|---|---|

| Filtration Efficiency (Micron Rating) | 10-20 microns (Gasoline) / 5-10 microns (Diesel) | 5 microns @ 99.5% (Gasoline) / 2 microns @ 99.9% (Diesel) | Superior protection for GDI/CRDI systems, extended injector life. |

| Pressure Drop (at nominal flow) | 0.2 - 0.5 bar | 0.1 - 0.25 bar | Reduced strain on fuel pump, consistent fuel delivery. |

| Contaminant Holding Capacity | 8 - 15 grams | 15 - 25 grams (or more, depending on model) | Longer service intervals, fewer replacements. |

| Operating Temperature Range | -30°C to 100°C | -40°C to 120°C | Reliable performance in extreme climates. |

| Burst Pressure | 6 - 8 bar | 10 - 15 bar | Enhanced safety margin against pressure spikes. |

| Material Compatibility | Standard gasoline/diesel | E85/Biodiesel compatible, chemical resistant | Versatility and longevity with modern fuels. |

| Service Life (Recommended) | 30,000 - 60,000 miles | Up to 100,000 miles (vehicle dependent) | Reduced total cost of ownership. |

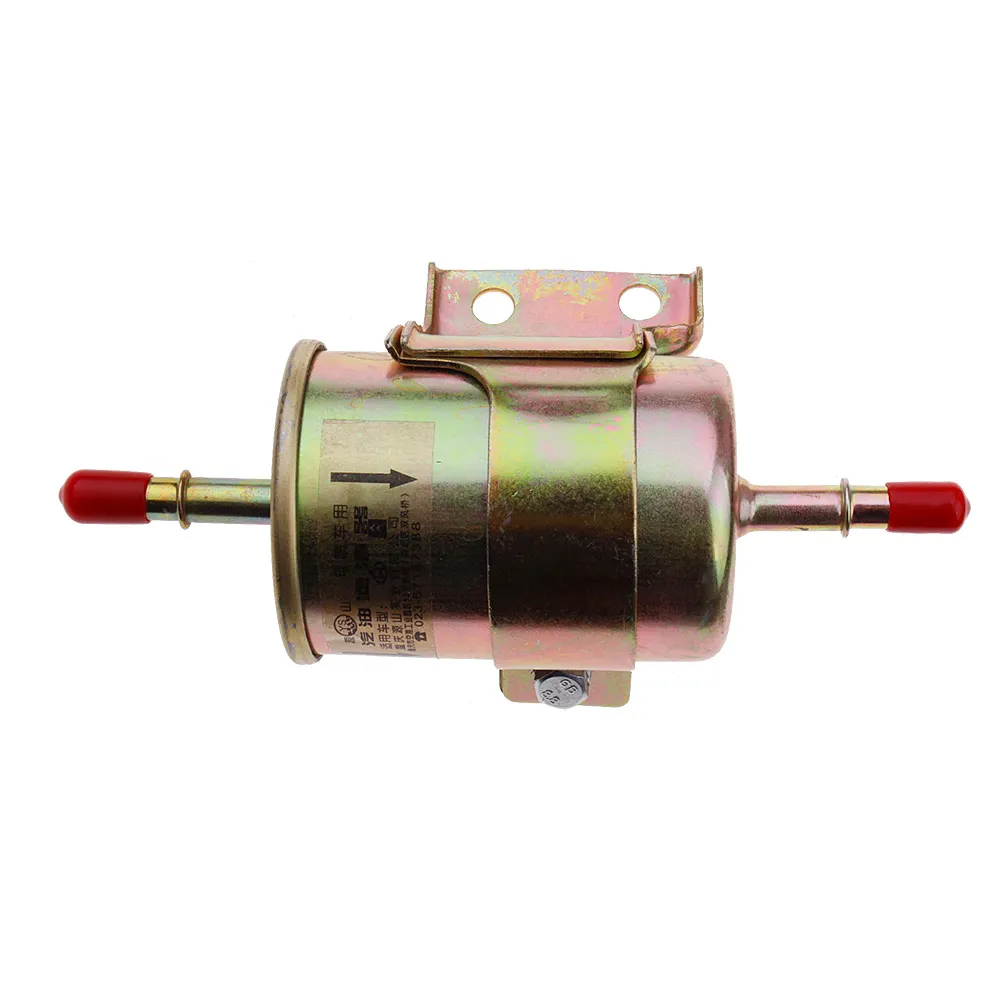

Fig 4: Our universal car fuel filter designed for broad compatibility and superior performance.

Customization Solutions and Application Cases

Recognizing the diverse needs of the global automotive industry, from OEM manufacturers to aftermarket suppliers and specialized applications, we offer extensive customization solutions for automotive filters. This adaptability ensures that our car fuel filter, and other filter products, can seamlessly integrate into various systems and meet unique performance requirements.

Customization Capabilities:

- Design-to-Specification (DTS): Working closely with clients, we can develop entirely new filter designs based on their specific engine parameters, space constraints, flow requirements, and target contaminant levels. This includes bespoke housing designs and mounting solutions for inline car fuel filter or in-tank configurations.

- Media Optimization: Tailoring the filter media type, density, and pleating geometry to achieve specific micron ratings and dirt-holding capacities, whether it's for high-performance sports cars, heavy-duty trucks, or specialized industrial vehicles.

- Material Selection: Customizing housing materials (e.g., specific grades of steel, aluminum, or engineering plastics) and seal compounds (e.g., Viton for aggressive fuels) to ensure compatibility and durability in harsh operating environments.

- Pressure and Flow Requirements: Engineering filters to handle extreme pressures (e.g., for high-pressure common rail diesel systems) or provide ultra-high flow rates for large displacement engines, while maintaining optimal filtration.

- Branding and Packaging: Offering private labeling and custom packaging solutions to align with client brand identities and logistics requirements.

Fig 5: Example of a custom-designed car fuel filter housing for specific vehicle models.

Real-World Application Cases:

Our automotive filters have been successfully deployed across a wide range of industries and challenging applications, demonstrating their versatility and reliability.

- Case Study 1: Heavy-Duty Mining Equipment

- Challenge: Mining environments expose vehicles to extreme dust and harsh operating conditions, leading to rapid clogging of conventional fuel filters and frequent downtime.

- Solution: We provided a customized car fuel filter featuring a multi-stage filtration system with an integrated water separator and a high-capacity synthetic media. The design prioritized robust construction and extended service intervals.

- Outcome: This solution resulted in a 40% reduction in fuel system maintenance, a significant increase in equipment uptime, and a noticeable improvement in fuel injector lifespan, showcasing our product's anti-corrosion and energy-saving capabilities in a demanding industry like metallurgy.

- Case Study 2: Public Transportation Fleet (Bus Company)

- Challenge: A major city bus operator faced issues with inconsistent fuel quality leading to premature wear of diesel engine components and elevated emissions. They needed a reliable inline car fuel filter that could handle varying fuel contaminants.

- Solution: We supplied a fleet-specific car fuel filter with enhanced fine-particle filtration (2-micron rating) and superior water-in-fuel separation technology. We also implemented a training program for their maintenance staff on optimal filter replacement.

- Outcome: The fleet experienced a 15% improvement in fuel economy, a 20% reduction in emission readings, and a significant decrease in fuel injector failures, leading to substantial operational cost savings and improved environmental compliance. This demonstrates utility in the public transport/logistics sector.

- Case Study 3: Specialized Marine Vessels

- Challenge: Marine diesel engines are highly susceptible to water contamination and microbial growth in fuel, which can cause severe damage. Standard filters were inadequate.

- Solution: We engineered a specialized marine fuel filter system, incorporating advanced hydrophobic media and a robust water collection bowl with a drain valve. The material selection was optimized for corrosion resistance in saltwater environments. This showcases applicability in marine and related sectors like petrochemicals (for fuel handling).

- Outcome: The new filter system virtually eliminated water-related fuel system issues, extended the life of fuel injectors and pumps, and ensured reliable engine operation even with fluctuating fuel quality, enhancing safety and reducing maintenance for the vessel operators.

Enhancing Trust and Authority: Our Commitment

At JYFilter, we understand that trust and authority are built on consistent performance, transparent practices, and unwavering commitment to quality. Our journey in the automotive filters industry spans over two decades, during which we have established ourselves as a reliable partner.

Our Authoritativeness & Trustworthiness:

- Industry Certifications: We are proud to hold ISO 9001:2015 certification for our quality management system, ensuring that every step from design to delivery meets the highest international standards. Many of our products also comply with SAE and DIN specifications.

- Strategic Partnerships: We collaborate with leading automotive component manufacturers and major aftermarket distributors globally, providing OEM-quality solutions. Our long-standing relationships are a testament to our reliability and product performance.

- Years of Service: With over 20 years of dedicated experience in filter manufacturing, our expertise is deeply rooted in practical knowledge and continuous innovation. This extensive service history allows us to provide seasoned insights into the nuances of car fuel filter design and application.

- Rigorous Testing and Validation: Every batch of automotive filters undergoes comprehensive testing in our state-of-the-art laboratory, including burst pressure tests, multi-pass efficiency tests (conforming to ISO 16889 standards where applicable), and contaminant holding capacity evaluations. Test data and reports are available upon request to demonstrate compliance and performance.

- Customer Feedback and Support: We maintain an open channel for customer feedback, which continually informs our product development and service improvements. Our dedicated customer support team provides expert guidance on product selection, installation, and troubleshooting, ensuring a seamless experience for every client.

Fig 6: Advanced quality control procedures for automotive filters ensuring product integrity.

Delivery and Warranty:

Delivery Cycle: For standard orders, our typical delivery lead time is 15-30 days, depending on order volume and specific product requirements. Expedited options are available for urgent needs. For customized solutions, lead times will be discussed and agreed upon during the project planning phase.

Quality Assurance & Warranty: We stand behind the quality of our automotive filters. All our products come with a comprehensive 12-month or 20,000-mile warranty (whichever comes first) against manufacturing defects. This commitment underscores our confidence in the durability and performance of our car fuel filter and other products, providing peace of mind to our customers.

Professional FAQ for **Automotive Filters**

Fig 7: Comparing value and performance for different car fuel filter price points.

Conclusion: Investing in Quality **Automotive Filters**

In conclusion, automotive filters are far more than simple consumables; they are sophisticated engineering marvels crucial for the health, efficiency, and longevity of any vehicle. The car fuel filter, in particular, stands as a frontline defense against fuel contamination, directly impacting engine performance, fuel economy, and emission compliance. As vehicle technologies evolve, so too must the filtration solutions that protect them. Our commitment to advanced manufacturing processes, rigorous quality control, and adherence to international standards ensures that our Car fuel filter (Product URL: https://www.jyfilter.com/car-fuel-filter.html) delivers unparalleled protection and value.

By understanding the technical parameters, appreciating the intricate manufacturing processes, and recognizing the critical role of filtration in various applications, vehicle owners and industry professionals can make informed decisions that safeguard their investments. Choosing high-quality automotive filters is not just about maintenance; it's about optimizing performance, reducing operational costs, and ensuring a cleaner, more sustainable future for transportation.

References & Further Reading:

- Grand View Research. (2023). *Automotive Filters Market Size, Share & Trends Analysis Report*. Retrieved from: https://www.grandviewresearch.com/industry-analysis/automotive-filters-market

- SAE International. (Current Standards). *SAE J905: Fuel Filter Test Methods*. Retrieved from: https://www.sae.org/standards/content/j905_200406/ (Note: Access usually requires subscription)

- ISO. (Current Standards). *ISO 16889: Hydraulic fluid power -- Filters -- Multi-pass method for evaluating filtration performance of a filter element*. Retrieved from: https://www.iso.org/standard/32952.html (Note: Access usually requires purchase)

- Filtration & Separation. (Various Articles). *Recent developments in automotive filtration technologies*. Retrieved from: https://www.filtsep.com/

-

The Hidden Benefits of Proper Cabin Filter Use in Your VehicleNewsJul.31,2025

-

Replacing Your Gasoline Filter at HomeNewsJul.31,2025

-

How Often Should You Replace Your Car Air Cabin Filter?NewsJul.31,2025

-

How Much Does a Car Air Filter Cost?NewsJul.31,2025

-

Car Fuel Filter Price GuideNewsJul.31,2025

-

Best Car Air Purifiers for Allergy SufferersNewsJul.31,2025

-

Vehicle Performance with Premium Car Filter SolutionsNewsJul.02,2025

Related Products