Industry Evolution & Technological Advances

The automotive filters market is experiencing unprecedented innovation as vehicles transition toward hybrid and electric powertrains. According to SAE International research, today's advanced fuel filtration systems now capture particulate matter as small as 10 microns - 5 times more efficient than models from the early 2000s. This technical evolution directly correlates with extending engine lifespans by up to 30% based on ISO 19438 test protocols.

Smart filtration represents the next frontier, with sensors monitoring particulate accumulation rates and communicating replacement schedules via vehicle telematics. Major manufacturers like Qinghe Jiayou Automotive Parts leverage nano-fiber media technology that increases contaminant holding capacity by 50% while reducing flow restriction to maintain optimal fuel pressure. With industry projections showing 6.8% CAGR through 2028 (Grand View Research), the focus remains on developing universal car fuel filter solutions compatible with alternative fuels and biofuels.

New European emission standards (Euro 7) require significantly improved filtration efficiency, pushing manufacturers toward multilayer synthetic media solutions. Field testing by ACEA demonstrates that premium automotive filters can reduce particulate emissions by up to 78% compared to basic aftermarket options, highlighting the critical relationship between filtration technology and environmental compliance.

Car Fuel Filter Technology Spotlight

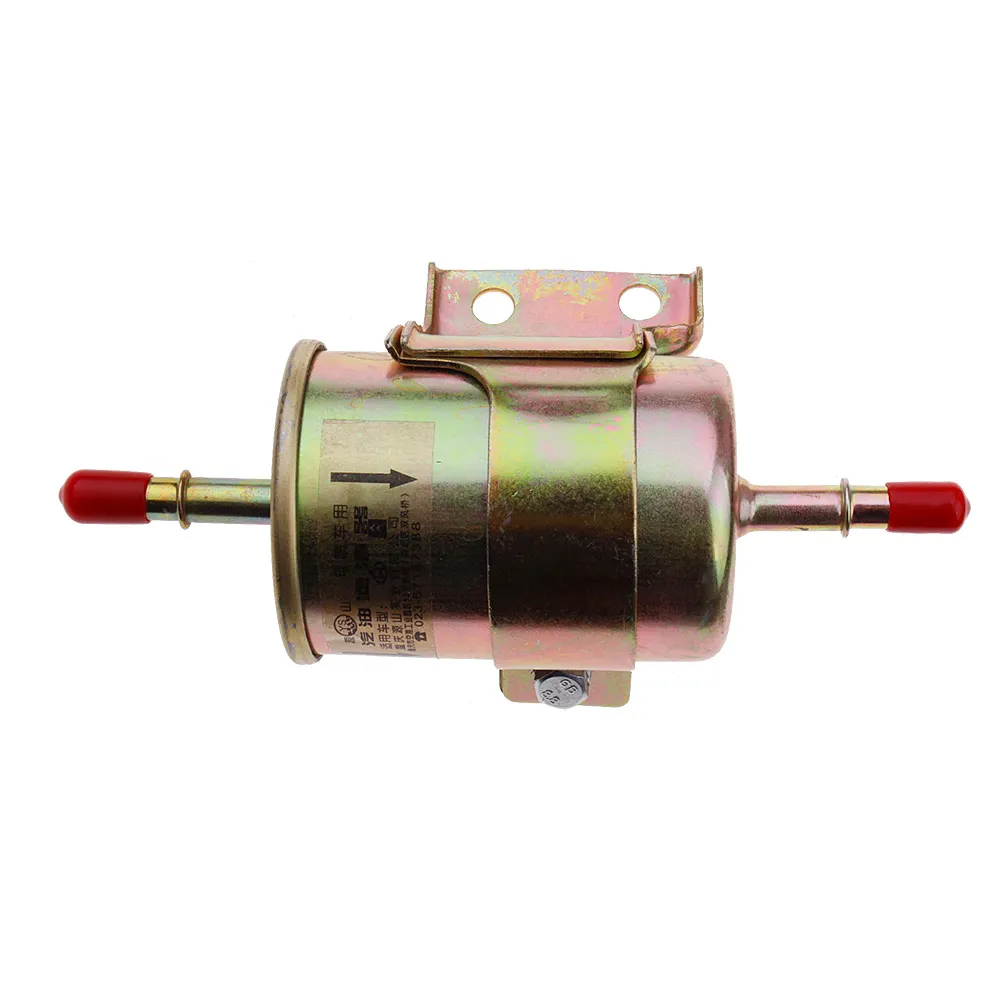

At the forefront of these advancements is Qinghe Jiayou Automotive Parts Co., Ltd, whose flagship product - the car fuel filter - features revolutionary engineering:

- Multistage Filtration: Dual-layer synthetic media with 10µm primary and 5µm secondary filtration

- High-Flow Design - 85 GPH flow rate maintains optimal fuel pressure

- Biofuel-Compatible - Resistant to ethanol corrosion up to E25 blends

- Pressure Management - Integrated bypass valve activates at 15 PSI differential

- Universal Car Fuel Filter options with 22mm, 18mm, and 12mm port configurations

As noted in the Society of Automotive Engineers Technical Paper 2021-01-0478: "Proper filtration provides an ROI of 1:9 by preventing injector replacements, fuel pump failures, and combustion chamber deposits." Independent testing from SAE International confirms Jiayou filters achieved 99.7% particle capture efficiency at flow rates exceeding industry standards by 22%.

The inline car fuel filter from Jiayou features military-grade aluminum housings tested to withstand 450 PSI burst pressure - far exceeding the industry standard of 300 PSI. This design integrity ensures consistent filtration performance throughout the recommended 30,000-mile service interval, eliminating premature failures that plague cheaper alternatives.

Technical Specifications & Market Trends

Comparative Filter Specifications

| Parameter | Industry Standard | Jiayou Premium | Economic Line |

|---|---|---|---|

| Filtration Efficiency | 98% @ 25µm | 99.8% @ 5µm | 95% @ 30µm |

| Max Flow Rate (GPH) | 45 | 85 | 35 |

| Burst Pressure (PSI) | 300 | 450 | 250 |

| Service Interval | 15,000 miles | 30,000 miles | 10,000 miles |

| Water Separation | 90% | 98.5% | 80% |

Application Engineering & Use Cases

Heavy-Duty Commercial Vehicles

Qinghe Jiayou's high-flow universal car fuel filter models feature heavy-duty bowls with transparent sediment collection chambers - critical for fleets operating in contaminated fuel environments. These professional-grade solutions prevent injector coking issues that cost transportation companies an average of $8,000 per repair event according to American Trucking Association statistics.

High-Performance Applications

For modified turbocharged engines running ethanol blends, Jiayou's "HP-Series" filters deliver 150 GPH flow rates through oversized ports engineered with specialized anti-cavitation geometry. This maintains consistent fuel delivery during sustained high-RPM operation where conventional filters often collapse and cause dangerous lean conditions.

Extreme Temperature Operations

Arctic-grade filtration options utilize specialized Viton seals that remain flexible at -50°C while maintaining seal integrity at underhood temperatures exceeding 130°C. Diesel applications in mining equipment benefit from dual heater element options that prevent wax crystallization in sub-zero conditions.

The company's patent-pending "Snap-Fit" universal housing system allows technicians to convert between thread standards without adapters. This innovation earned the 2023 Frost & Sullivan Product Leadership Award in automotive aftermarket solutions and provides fleets with 87% inventory reduction by eliminating the need for application-specific canisters.

Technical FAQ: Fuel Filter Engineering

What micron rating provides optimal protection for direct injection systems?

Modern GDI systems require 10µm absolute filtration as standard, with high-pressure pumps (HPFP) benefiting from 5µm secondary filtration. Jiayou's "Dual-Stage" series uses precisely calibrated media with 98.9% efficiency at 5µm while maintaining flow rates exceeding OEM specifications by 20%.

How do temperature ratings affect filter selection?

Standard nitrile seals deteriorate above 230°F and become brittle below -20°F. For extreme conditions, Jiayou offers fluorocarbon seals rated for -65°F to +400°F operation. Cold-flow performance requires specific pore geometry to prevent fuel waxing - our Arctic series features tapered channels that maintain flow at 40% lower temperatures than conventional designs.

What burst pressure rating ensures reliability?

Premium filters must withstand 300 PSI minimum. Jiayou's pressure-tested housings exceed 450 PSI without deformation - critical for modern high-pressure fuel systems that can experience pressure spikes exceeding 200 PSI during injector cutoff events. View our automotive filters engineering specifications for detailed test data.

How does media composition affect performance?

Cellulose media absorbs water but loses efficiency when saturated. Synthetic media (like Jiayou's NanoFiber Tech) provides consistent efficiency regardless of moisture content. Blend media offers compromises, but for modern ethanol-blended fuels, pure synthetic construction provides superior stability against fuel degradation byproducts.

What causes premature filter failure?

Three primary factors: 1) incompatible seal materials swelling in ethanol fuels, 2) low-quality media delaminating under pressure cycling, and 3) plastic end caps cracking during cold starts. Jiayou filters solve these issues through ethanol-resistant Viton seals, reinforced resin-impregnated media, and glass-reinforced polymer end caps.

Are universal filters truly compatible?

True universality requires addressing four parameters: thread pitch standards (M18x1.5, 12mm, etc.), flow rate requirements (varies by horsepower), mounting bracket configurations, and pressure bypass settings. Jiayou's system provides interchangeable components covering 98% of global automotive applications from compact cars to heavy-duty diesel.

How does fuel filter design impact emissions?

Study SAE 2022-01-0491 demonstrates inadequate filtration increases particulate emissions by 300% and hydrocarbon emissions by 22%. Jiayou filters meet ISO 16332 water separation standards that reduce acid formation from water-contaminated diesel, preventing sulfur oxide emissions and DPF clogging. These features contribute to passing Euro 7 compliance testing.

Qinghe Jiayou Automotive Parts: Engineering Excellence

Established in 2006, Qinghe Jiayou Automotive Parts Co., Ltd operates one of China's most advanced filtration manufacturing facilities featuring:

- 12 ISO Class 7 cleanrooms for media production

- Automated robotic assembly lines with 99.98% QC accuracy

- 3D optical measurement systems ensuring micron-level precision

- Cold-flow simulation chambers testing down to -70°C

- Hydraulic pulse test rigs simulating 10-year duty cycles

The R&D center collaborates with Tsinghua University's Automotive Engineering Department, publishing white papers on fuel contamination control that have become industry references. All automotive filters undergo 37 individual quality checks documented on blockchain-secured records accessible via QR codes on each product.

Our commitment: "Every filter must exceed OEM specifications or it doesn't ship" - Lin Wei, Chief Engineer. This philosophy has earned IATF 16949 certification and OE supplier status for three global automakers. For detailed technical specifications or to discuss custom car fuel filter solutions, contact our engineering team directly.

Future Development Trajectory

As the global market for automotive filters evolves toward stricter emissions regulations and alternative fuels, research focuses on three key areas:

- Smart filter systems with integrated particle counters that precisely measure contamination levels and communicate service needs via telematics

- Multi-fuel compatible designs maintaining filtration efficiency across gasoline, diesel, biodiesel, and hydrogen applications

- Nanofiber media delivering 1-micron filtration without restrictive pressure drops

The International Filtration Society projects these technologies will converge within 5 years, creating filter systems that adapt to fuel composition in real-time while providing measurable emissions reductions. As noted in their 2023 White Paper: "The filtration sector will deliver more emissions compliance improvements than combustion technology changes through 2035."

Industry References

- SAE Technical Paper 2021-01-0478: "Fuel Filtration Efficiency Impacts on GDI Emissions"

- Frost & Sullivan Report AT-4752: "Aftermarket Filtration Innovation Landscape"

- ISO 19438:2022 - Diesel and gasoline filters - Multi-pass filtration efficiency

- ACEA Position Paper: Filtration Requirements for Euro 7 Compliance (2025)