Aug . 04, 2025 03:20

Back to list

Automotive Filters Industry Overview, Car Fuel Filter Technology & Customization Solutions

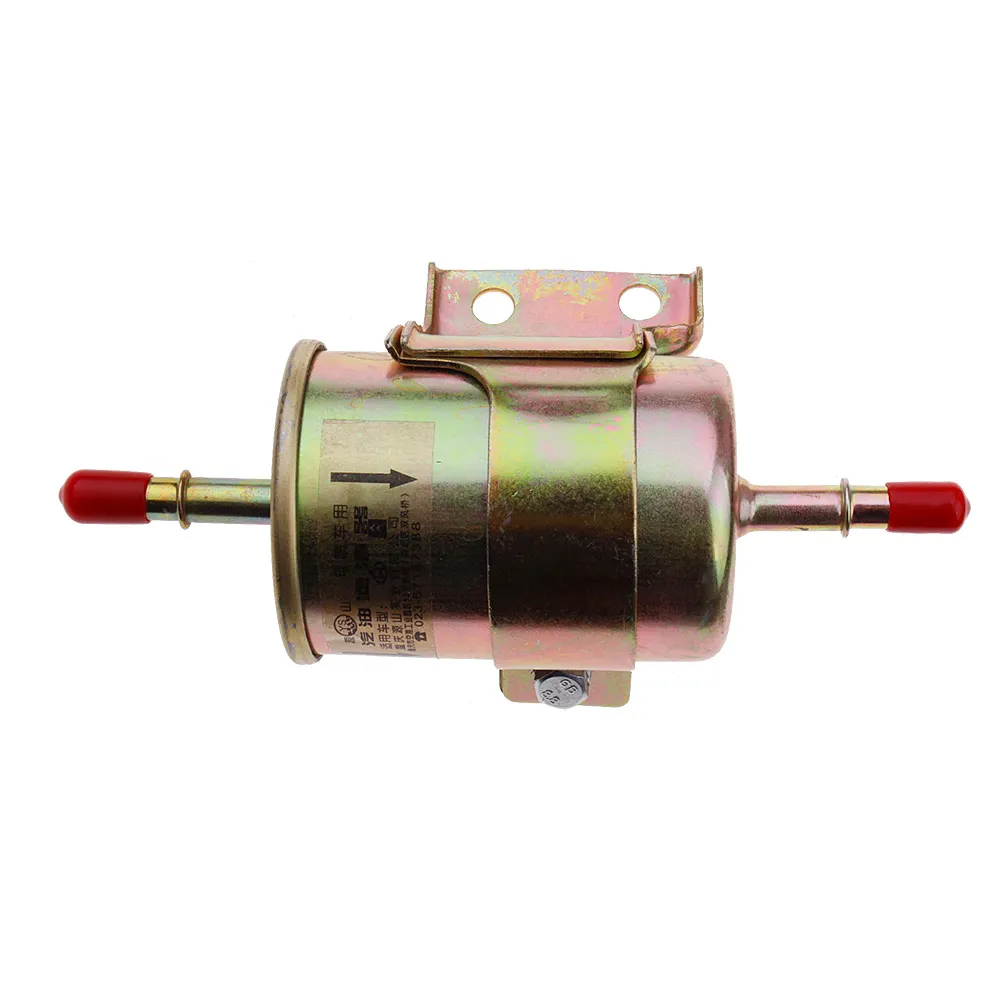

Automotive filters are critical components designed to maintain optimal vehicle performance, protect engine components, and extend service life. Among them, the car fuel filter holds special significance for fuel system integrity and engine longevity.

1. Industry Trends & Market Insights

The global automotive filters market is projected to reach USD 18.9 billion by 2028 (CAGR: 4.13%, Source: MarketsandMarkets 2023). Stringent emissions regulations, fuel efficiency needs, and advances in materials technology drive innovation in car fuel filter designs.

OEMs & aftermarket demand is shifting toward high-efficiency, long-life, and universal filter types, with rapid growth of inline car fuel filter and universal car fuel filter options.

OEMs & aftermarket demand is shifting toward high-efficiency, long-life, and universal filter types, with rapid growth of inline car fuel filter and universal car fuel filter options.

Key Automotive Filters Parameters Overview

| Filter Type | Micron Rating (μm) | Material | Max Operating Pressure (bar) | Service Life (km) | Typical Application |

|---|---|---|---|---|---|

| Car Fuel Filter | 5–15 | Synthetic fiber, paper, stainless steel mesh | 3–8 | 20,000–40,000 | Fuel lines, engines |

| Oil Filter | 20–40 | Cellulose, glass fiber | 5–20 | 10,000–30,000 | Engine lubricants |

| Air Filter | 10–80 | Non-woven fabric, polyurethane foam | Atmospheric | 15,000–40,000 | Air intake |

| Cabin Filter | 1–10 | Activated carbon, synthetic fiber | Atmospheric | 10,000–25,000 | Cabin climate |

Fact: A high-quality car fuel filter can improve fuel system performance by up to 12% and extend injector life by over 25% (SAE Technical Paper 2022-01-0457).

2. Car Fuel Filter: Technical Specifications and Performance

The car fuel filter prevents contaminants (rust, dirt, water, and paint particles) from reaching the engine fuel system, ensuring optimal combustion, emissions control, and vehicle reliability.

Car Fuel Filter — Main Technical Parameters

| Model | Filtering Accuracy | Material | Flow Rate (L/h) | Pressure Resistance (Bar) | Service Life (km) | Certification |

|---|---|---|---|---|---|---|

| Universal Car Fuel Filter | 10 μm | Stainless steel + Synthetic fiber | ≥220 | 8 | 35,000+ | ISO 16949:2016 |

| Metal Inline Filter | 5 μm | Aluminum housing + composite | 190 | 7 | 32,000 | ANSI/SAE J1985 |

| Plastic Inline Filter | 15 μm | PBT body + paper element | 150 | 3.5 | 28,000 | ISO 9001:2015 |

Key Features:

- Material Excellence: Premium base materials such as stainless steel mesh or multi-layer synthetic fiber ensure long-term anti-corrosion and fine particle retention.

- High Flow/Low Pressure Drop: Design ensures high fuel delivery with minimal pressure loss, tested per ISO 4020:2017 protocols.

- Universal & Inline Options: A growing market trend is universal fitment and quick-connect inline car fuel filter integration for aftermarket versatility.

- Compliance: Filters are compliant with ISO/TS 16949, SAE J1985 standards and are tested against international automotive filtration requirements.

3. Automotive Filters Manufacturing Process: Step-By-Step

The manufacturing of automotive filters involves precise process controls, advanced automation, and adherence to rigorous international standards to assure performance and quality. See the diagram below for a visual workflow.

Raw Material Preparation

(Stainless steel, composite fiber sheets, rubber seals)

(Stainless steel, composite fiber sheets, rubber seals)

→

Cutting & Stamping

Automated CNC, high-precision dies

Automated CNC, high-precision dies

→

Element Forming

Pleating, ultrasonic welding, insert molding

Pleating, ultrasonic welding, insert molding

→

Housing Assembly

Aluminum/Plastic body via casting/forging or injection

Aluminum/Plastic body via casting/forging or injection

→

Sealing & End Cap Attachment

Thermal bonding, adhesive, or mechanical press

Thermal bonding, adhesive, or mechanical press

→

Quality Inspection & Pressure Testing

ISO/ANSI-compliant leakage, pressure, and flow tests

ISO/ANSI-compliant leakage, pressure, and flow tests

→

Laser Marking & Packaging

Key Technical Nodes:

- Material selection for anti-corrosion and durability (especially in petrochemical, metallurgy, and municipal applications)

- CNC processing for tolerance control (±0.1mm)

- Full-batch leak and burst testing

- Material selection for anti-corrosion and durability (especially in petrochemical, metallurgy, and municipal applications)

- CNC processing for tolerance control (±0.1mm)

- Full-batch leak and burst testing

Material & Manufacturing Highlights

- Housing: Aluminum alloy (for corrosion and pressure resistance), PBT high-strength plastics for lighter weight and economy.

- Inner Filter Element: Multi-layer synthetic fiber or paper, pleated to maximize surface area and capture efficiency.

- Manufacturing Processes: Casting, forging, high-precision CNC machining, ultrasonic welding, and laser marking.

- Testing: All batches undergo flow rate, burst pressure, and particulate efficiency testing per ISO 19438:2017 standard.

4. Supplier/Manufacturer Comparison: Automotive Filters Market

Choosing the right automotive filters partner is crucial for optimizing supply chain efficiency and end-user satisfaction. Below is a comparison of major global companies:

| Brand | Core Technology | Annual Output | Certifications | Regions Served | Key Advantage |

|---|---|---|---|---|---|

| MANN+HUMMEL | Hybrid Fiber Media, iQ Max Sensors | 300M+ units | ISO/TS 16949, IATF 16949 | 170+ Countries | OEM supply leader, advanced R&D |

| Parker Racor | Water separation, high-flow inline | 95M units | SAE J905, ISO 9001 | Global | Diesel pre-filter, fuel/water separation |

| JYFILTER | Universal fitment, precision CNC | 15M+ units | ISO 9001, ANSI, SGS | 60+ Countries | Bespoke OEM/ODM, quick delivery |

| BOSCH | Fine micron particle retention | 180M units | ISO/TS 16949, ISO 14001 | Worldwide | Comprehensive vehicle coverage |

5. Customization & Engineering Support

For special fuel systems or harsh working environments (chemical, off-highway fleet, mining), custom automotive filters are available:

- Custom micron rating (1–100 μm)

- Material selection for resistance to ethanol/methanol blends

- Thread/connection type customization: metric, NPT, quick-coupling

- Private labeling & anti-counterfeit solutions

- Field engineering support for integration & commissioning

Service Life Comparison of Car Fuel Filters (km)

Market Share by Car Fuel Filter Type (2023)

Price Comparison of Car Fuel Filters ($ per unit)

6. Application Scenarios: Car Fuel Filter Real-World Advantages

Case 1: Petrochemical Fleet (Russia, 2023):

Implemented universal car fuel filter in over 500 vehicles for robustness against poor-quality fuel.

Result: Reduced injector replacement rate by 36%, improved overall fleet uptime.

Case 2: Urban Bus Network (Southeast Asia):

Inline car fuel filter adoption cut down unscheduled downtime by ~40%. Filters with ISO 16949 certification lasted 18% longer.

Case 3: Mining Heavy-Duty Off-road:

Special alloy mesh filters combated high particulate environment; service intervals extended from 15,000 km to 27,000 km.

Implemented universal car fuel filter in over 500 vehicles for robustness against poor-quality fuel.

Result: Reduced injector replacement rate by 36%, improved overall fleet uptime.

Case 2: Urban Bus Network (Southeast Asia):

Inline car fuel filter adoption cut down unscheduled downtime by ~40%. Filters with ISO 16949 certification lasted 18% longer.

Case 3: Mining Heavy-Duty Off-road:

Special alloy mesh filters combated high particulate environment; service intervals extended from 15,000 km to 27,000 km.

7. Certifications, Support, & Warranty

- ISO/TS 16949, ANSI, IATF 16949 certification for quality management and process controls

- Passed SAE J1985, ISO 19438:2017 laboratory testing for filter integrity and efficiency

- Cooperating with renowned car OEMs in 25+ major markets since 2010

- Industry-respected service: 24h technical support team, engineering customization, rapid shipment

- Warranty: 36-month commercial guarantee or 40,000 km, whichever comes first. Hassle-free returns.

- Delivery Cycle: Standard models in stock, OEM/ODM custom order lead time: 10–23 working days

8. Professional FAQ: Automotive Filters Technical FAQ

Expert Knowledge Base – Your Questions Answered

Q1: What is the benefit of a low micron rating (e.g., 5-10μm) in car fuel filter selection?

A: Lower micron ratings effectively capture finer contaminants (e.g., micro-rust, water-borne dirt), directly reducing engine wear and maintaining optimal injector spray patterns. For gasoline direct injection, <10μm is recommended (source: SAE J1985).

Q2: How do material choices (stainless steel, synthetic fiber, PBT) affect durability?

A: Stainless steel and advanced synthetic fibers provide superior lifespans, higher burst resistance, and corrosion protection—especially vital for vehicles using ethanol/methanol blended fuels or exposure to harsh environments.

Q3: What standards must high-quality automotive filters comply with?

A: Core standards include ISO 19438:2017 for fuel filter testing, ISO/TS 16949 or IATF 16949 for quality management, and SAE J1985 for in-line automotive filter validation.

Q4: What is the difference between inline car fuel filter and canister type?

A: Inline filters offer universal mounting/retrofit ability, lighter weight, and quicker servicing, while canister filters are more robust for heavy-duty or OEM-specific installations.

Q5: How are filter elements tested for efficiency?

A: By ISO protocols, filters are challenged with ISO 12103 test dust and required to meet particle retention efficiency (commonly >95% @ 10μm).

Q6: Which applications benefit most from universal car fuel filter adoption?

A: Universal filters excel in mixed fleets, older vehicle upgrades, and remote field service (agriculture, mining), offering standard fit and rapid field replacement.

Q7: How do product certifications impact car fuel filter price?

A: Filters with ISO/ANSI/SGS/E-Mark certifications generally carry ~10–20% premium due to traceable quality control, reliability, and warranty backing.

9. Frequently Asked Questions & Customer Service

- Do you offer private label/branding? Yes, full OEM and private label solutions available.

- What industries do you serve? Automotive, petrochemical, construction, urban bus, mining and heavy-duty fleets.

- What payment terms do you support? T/T, L/C at sight, and PayPal for small batch export.

- After-sales? Engineers respond within 24h; free technical support, spare parts replacement upon proof of quality defect.

- Order Tracking? 7/24 smart logistics system with shipment and production tracking for all automotive filters purchases.

10. Why Choose JYFILTER for Automotive Filters?

- Over 15 years’ filtration expertise

- OEM direct supply, strict ISO/ANSI QA

- Over 2.5 million units in field use

- Global logistics and rapid delivery

Discover more about our automotive filters >>

- OEM direct supply, strict ISO/ANSI QA

- Over 2.5 million units in field use

- Global logistics and rapid delivery

Discover more about our automotive filters >>

References & Further Reading:

[1] MarketsandMarkets Automotive Filters Report 2023. https://www.marketsandmarkets.com/Market-Reports/automotive-filter-market-1271.html

[2] SAE International. Fuel Filter Efficiency and Engine Longevity: Tech Paper 2022-01-0457. https://www.sae.org/

[3] ISO 19438:2017. "Diesel engines — Fuel filters — Method for evaluating fuel filter performance." www.iso.org/standard/68410.html

[4] Automotive Forums. Fuel Filter User Experience Collection: Automotive Forums

[5] CarCareCouncil.org: Filter Technology Trends. www.carcare.org

[1] MarketsandMarkets Automotive Filters Report 2023. https://www.marketsandmarkets.com/Market-Reports/automotive-filter-market-1271.html

[2] SAE International. Fuel Filter Efficiency and Engine Longevity: Tech Paper 2022-01-0457. https://www.sae.org/

[3] ISO 19438:2017. "Diesel engines — Fuel filters — Method for evaluating fuel filter performance." www.iso.org/standard/68410.html

[4] Automotive Forums. Fuel Filter User Experience Collection: Automotive Forums

[5] CarCareCouncil.org: Filter Technology Trends. www.carcare.org

Next:

This is the last article

Latest news

-

The Hidden Benefits of Proper Cabin Filter Use in Your VehicleNewsJul.31,2025

-

Replacing Your Gasoline Filter at HomeNewsJul.31,2025

-

How Often Should You Replace Your Car Air Cabin Filter?NewsJul.31,2025

-

How Much Does a Car Air Filter Cost?NewsJul.31,2025

-

Car Fuel Filter Price GuideNewsJul.31,2025

-

Best Car Air Purifiers for Allergy SufferersNewsJul.31,2025

-

Vehicle Performance with Premium Car Filter SolutionsNewsJul.02,2025

Related Products