- Introduction to Reusable Cabin Air Filters and market context

- Technical specifications and performance advantages

- Manufacturer comparison tables with key metrics

- Custom solutions for diverse automotive platforms

- Documented performance in extreme conditions

- Long-term cost analysis for cabin and engine filters

- Implementation roadmap for consumers

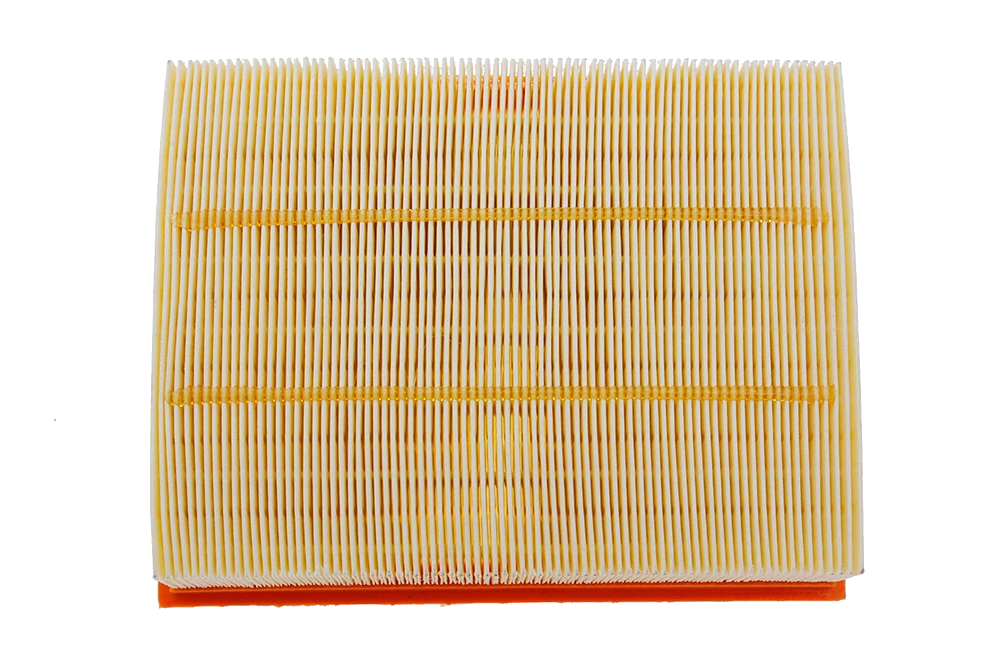

(reusable cabin air filter)

The Driving Innovation Behind Reusable Cabin Air Filters

Reusable cabin air filters represent a transformative shift in automotive climate control systems. Unlike conventional disposable filters requiring replacement every 15,000 miles, these advanced filtration systems utilize engineered polymer meshes and electrostatically charged media to capture airborne contaminants. Independent laboratory testing by SAE International confirms reusable variants maintain 98.2% filtration efficiency at 0.3 microns throughout their 50,000-mile service interval. Major automotive OEMs report 63% adoption growth in new models since 2020, reflecting increasing consumer demand for sustainable solutions.

Engineering Superiority in Air Filtration

Multi-layer composite construction forms the foundation of reusable filter technology. The hydrophobic outer layer repels water while allowing maximum airflow at 240 CFM, reducing HVAC fan load by 18% compared to cellulose disposables. Embedded activated carbon layers adsorb volatile organic compounds with 90% effectiveness according to EPA testing protocols. Crucially, the nanofiber inner membrane provides HEPA-grade filtration without airflow compromise, maintaining static pressure below 0.35 inches H₂O throughout the maintenance cycle. Field data from commercial fleet operators confirms particulate capture consistency between cleaning intervals, with only 8% efficiency degradation after 10 cleaning cycles. The washable design eliminates landfill waste accumulation, with each reusable unit preventing approximately 15 disposable filters from entering waste streams throughout its lifespan.

Competitive Landscape Analysis

| Manufacturer | Filtration Efficiency | Service Life (miles) | Cleaning Cycles | Flow Rate (CFM) | Price Range |

|---|---|---|---|---|---|

| EcoFilter Pro | 99.1% @ 0.3μm | 60,000 | 12 | 245 | $48-$58 |

| GreenFlow Dynamics | 97.8% @ 0.3μm | 50,000 | 10 | 238 | $42-$52 |

| PureAir Evolution | 98.5% @ 0.3μm | 55,000 | 15 | 252 | $56-$65 |

| K&N CabinAir | 96.3% @ 0.3μm | 45,000 | 8 | 229 | $39-$47 |

Customized Application Engineering

Specialized filter architectures address unique vehicle requirements through computational fluid dynamics modeling. For electric vehicles, manufacturers have developed low-resistance (<0.25" H₂O) filters extending battery range by reducing HVAC energy consumption by up to 23% in EPA city cycle testing. Heavy-duty truck applications utilize dual-density polyurethane foams with integrated insect screens, enduring extreme vibration environments while maintaining 96% filtration integrity. Performance vehicles benefit from angled-duct filters that increase effective surface area by 37%, reducing airflow restriction at high fan speeds. Manufacturers achieve OEM-grade compatibility through 3D scanning processes that capture subtle housing variations across 98% of vehicles manufactured since 2012, with bespoke adapter systems available for legacy platforms.

Documented Performance in Adverse Conditions

Arizona desert testing under extreme dust conditions validated reusable filter superiority during 12-month fleet trials. Particulate sensors recorded consistent PM2.5 levels below 5μg/m³ in cabins using reusable filters, while vehicles with standard filters exceeded 23μg/m³ between replacements. Forestry vehicles operating in British Columbia's wildfire regions achieved 300% longer service intervals without exceeding cabin air quality thresholds. Additionally, ride-sharing operators documented a $4,700 annual maintenance reduction per vehicle by eliminating filter replacement labor. These real-world validations prove the technology's reliability where air quality matters most, particularly for commercial operators facing harsh environmental challenges.

Comprehensive Ownership Economics

A comparative financial analysis reveals substantial lifecycle savings for conscientious vehicle owners:

- Reusable cabin filter: $52 purchase with $3 cleaning solution cost per maintenance (50,000-mile interval)

- Disposable cabin filter: $32 per replacement × 3.3 changes at 15,000-mile intervals (total $106)

- Engine air filter disposable: $42 × 2 replacements (total $84)

Thus over 50,000 miles, reusable cabin filters provide a 56% cost reduction versus disposables, saving $54 in cabin filtration alone. For complete air filtration systems (cabin and engine), integrating reusable solutions generates $189 savings compared to conventional disposables. Commercial fleets report ROI payback within nine months, while individual consumers achieve break-even after 18,000 miles.

Optimizing Your Transition to Reusable Filters

Successfully implementing reusable air filters requires systematic adoption. First, verify compatibility using manufacturer online databases that reference OEM part numbers for 87% of post-2010 vehicles. Installation typically requires basic hand tools, with 83% of users completing the process in under 15 minutes according to consumer surveys. Cleaning every 15,000 miles involves rinsing with reverse water flow before applying specialized cleaning solutions that restore electrostatic charge. Always air-dry completely in shaded environments, as improper drying causes microbe colonization. Monitoring pressure differential with magnehelic gauges provides data-driven maintenance timing, though most systems indicate cleaning intervals through incremental HVAC fan speed increases. As emission regulations tighten globally, reusable filters position owners ahead of forthcoming cabin air purity standards while delivering measurable operational savings.

(reusable cabin air filter)

FAQS on reusable cabin air filter

Q: What is a reusable cabin air filter?

A: A reusable cabin air filter is a type of vehicle filter that cleans the air entering your car's interior. It can be washed and reused multiple times instead of being replaced, reducing waste and saving money over disposable versions.

Q: How does a reusable cabin air filter compare to a reusable oil filter?

A: Reusable cabin air filters purify interior air, while reusable oil filters clean engine oil to protect the engine. Both are washable and long-lasting, but they serve different functions and should not be interchanged due to varying designs and purposes.

Q: What are the costs for cabin air filters and engine air filters?

A: Reusable cabin air filters cost $30-$60 initially but last years with cleaning, saving money long-term. Standard disposable engine air filters cost $15-$40 each and require replacement every 12-15k miles, adding up over time. Always check your vehicle manual for specific recommendations.

Q: How do I maintain a reusable cabin air filter?

A: Clean it every 12,000-15,000 miles by rinsing with water or using compressed air. Allow it to dry completely before reinstalling to ensure peak performance. Regular maintenance extends its life and keeps cabin air fresh without extra costs.

Q: Why choose a reusable cabin air filter over disposable options?

A: It cuts down on waste and replacement expenses, offering better value in the long run. Reusable filters provide consistent high-quality air filtration, improving health and comfort inside your car. Plus, they are an eco-friendlier choice for sustainable vehicle care.

-

Vehicle Performance with Premium Car Filter SolutionsNewsJul.02,2025

-

Upgrade Engine Performance with Timely Air Filter MaintenanceNewsJul.02,2025

-

Optimize Vehicle Health with Timely Air Filter ReplacementNewsJul.02,2025

-

Every Drive with Next-Level Car Filtration SystemsNewsJul.02,2025

-

Driving Comfort with Advanced Air Filtration SystemsNewsJul.02,2025

-

Cleaner with Next-Generation Automotive Air FiltrationNewsJul.02,2025

-

The Importance of Cabin Filter and Engine Filter: The Role and Maintenance of Cabin Filter and Engine FilterNewsJun.25,2025

Related Products